Basic Info

Basic Info Model NO.: JTXE

Product Description

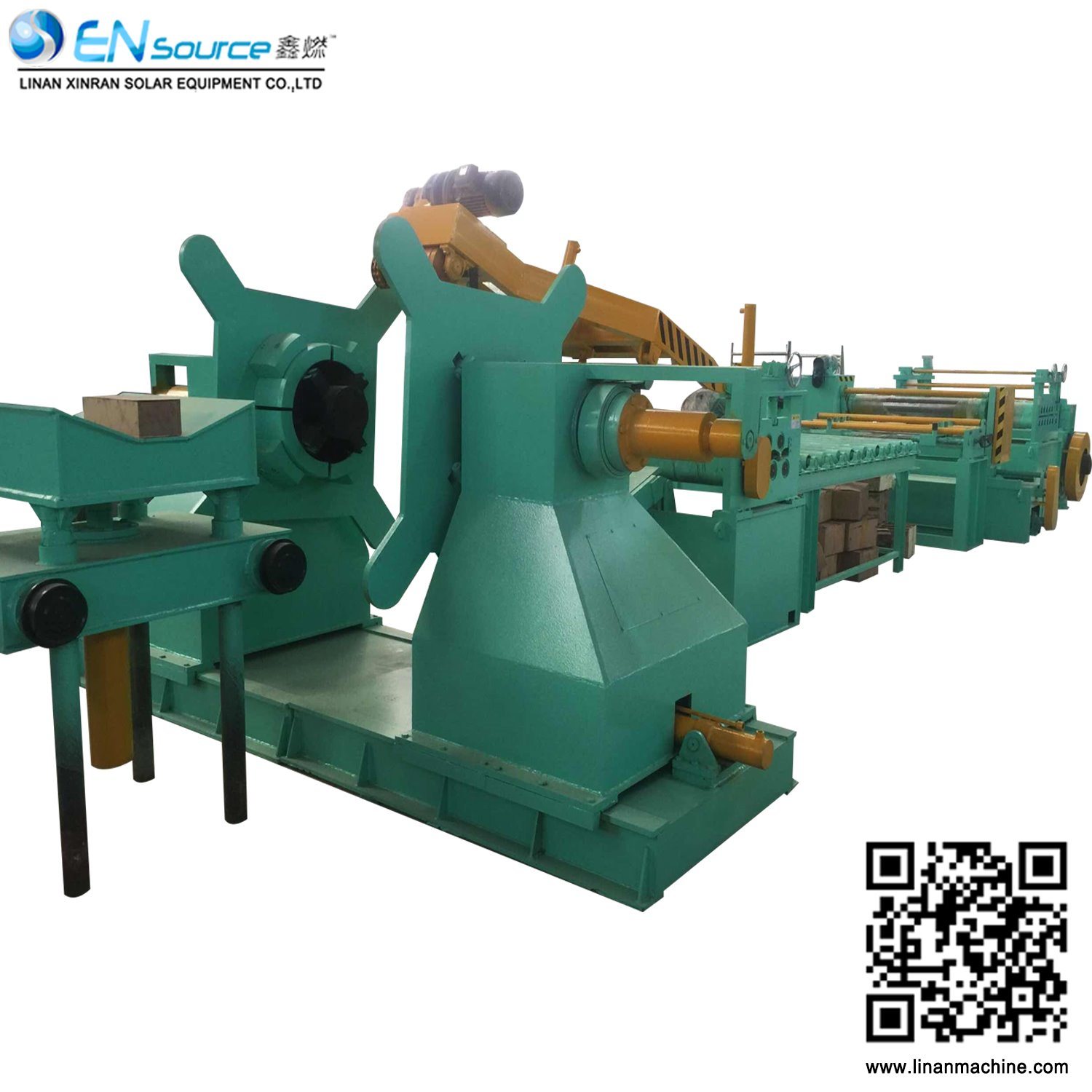

China Centralized Positioning Silicon Steel Cut to Length Line

Basic Info

Model NO.: JTXE-LL-600ZX PLC: Mitsubishi, or Siemens Certificate: ISO Warranty: 1 Year After-Sell Service: Yes Trademark: XIEER Transport Package: Seaworthy Packing Specification: 15*2.5m Origin: Jiangyin HS Code: 84623920Product Description

JTXE-LL-600ZX Transformer Steel Core Cut to Length LineCut to Length Line Process Introduction

Two shearing two punching silicon steel cutting line with step-lap is an automatic production line for the silicon steel sheet shearing, consists of the following parts:Uncoiler, Feed buffer, Feeder, Punch parts, Shear parts, Conveyor, Material machine, Pneumatic system, Electronic control system.

Cut to Length Line Working Flow

Cut to Length Line Composition

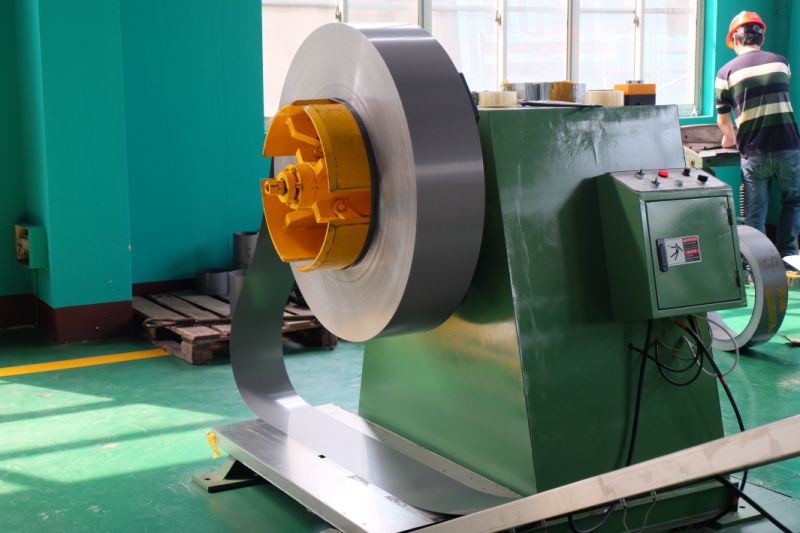

1,Single head hydraulic material rack

Coil inner diameter(mm)495-510Coil max outer diameter(mm)1200Expand scope of the expansion head(mm)470-520Coil max width(mm)420Single head max loading weight(t)1.5Function:the opening head is composed of four flaps,automatically tighten or loosen the coil.According to feeding speed,synchronous non-pole speed adjustment,realize the open volume function.

2,No pit slope material guide equipment

Function:adopt slope buffer guide,it consists of an inclined guide plate and a detection switch. The test switch is installed>3,Feeding material equipment

Double roll structure,the equipment is composed of a fixed scale roller,servo motor,synchronous belt wheel reducer,base and so>Measuring roll:2, down roll is made of Gcr15 steel alloy,after adjustment ,quenching treatment,polishing after grinding ,upper roller outer round polyurethane.Control:Taida servo driveupper roller can manually control lifting up and down.

4,Punching section

A set of V shape punching, a set of hole shape punchingO shape punching is driven by the servo motor directly connected with the crankshaft to drive the upper die down to the O shape hole.Hole diameter 10-20V shape punching is driven by the servo motor belt reducer to drive the upper die from the top down to make the V-shape.V shape punching can realize stepping function by inwardly adjusting the motor.

5,Cutting section

Cutting blade material:hard steel alloyThe cutting mode is driven by the servo motor belt reducer to drive the crankshaft.Function:according to the drawing requirement,cut the edge pieces,yokes,middle column and so>6,Conveyor

Function:the conveyor is driven by a AC1.5kw motor to drive the steel core strip from the punching section, and the cutting section, and shears are cut off and then transferred to the transfer device of the material receiving mechanism.

7,Material sorting device

Distributing device:the different shape of the strip is transmitted to different pressure feeding devices through the opening and closing of the deviding plate.

Pressing device:automatically separate the two kinds of strip shape by pneumatic tensioning device.

8,Pneumatic system

Provide power to the cylinder of production line

9,Electronic control system and operation system

Parameters

1,High Speed High Precision Slitting LineModel NameJT1250Cutting Thickness(mm)0.23-0.5Cutting Width(mm)40-1200Coil Weight(t)5Feeding Speed(m/min)80-120Straightness Deviation of Each Edge(mm/m)0.1Cutting Angle Accuracy DEG?.025Band Width Accuracy(mm)?.1Total Motor Power(KW)55

2,Precision high speed cut-to-length linenonstop cutting

Two cutting two punching(ordinary type)Model NameJTXE-LL-300JTXE-LL-400Cutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-30040-400Cutting Length(mm)350-9999350-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)1516.5

Two cutting two punching(step type)Model NameJTXE-LL-300ZJTXE-LL-400ZCutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-30040-400Cutting Length(mm)350-9999350-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)2021.5

Two cutting two punching(centralized positioning)Model NameJTXE-LL-400ZXJTXE-LL-600ZXCutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-40060-600Cutting Length(mm)350-9999350-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)2426

3,Precision high speed cut-to-length line nonstop cutting

Two cutting>Model NameJTXE-X-300JTXE-X-400JTXE-X-600Cutting Thickness(mm)0.23-0.350.23-0.350.23-0.35Cutting Width(mm)40-30040-40060-600Cutting Length(mm)350-9999350-9999350-9999Feeding Speed(m/min)180180180Cutting Burr(mm)≤0.02≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025?.025Cutting Length Accuracy(mm)?.1?.1?.1Total Motor Power(KW)1213.513.5

4,Center Post Silicon Steel Cut to Length Line(step type)Model NameJTXE-ZZ-300ZJTXE-ZZ-400ZCutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-30040-400Cutting Length(mm)150-9999150-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)1414

5,Electric Reactor Silicon Steel Cut to Length LineModel NameJTXE-300JTXE-400JTXE-600Cutting Thickness(mm)0.23-0.50.23-0.50.23-0.5Cutting Width(mm)40-30040-40040-600Cutting Length(mm)10-999910-999910-9999Feeding Speed(m/min)180180180Cutting Burr(mm)≤0.02≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025?.025Cutting Length Accuracy(mm)?.05?.05?.05Total Motor Power(KW)101012

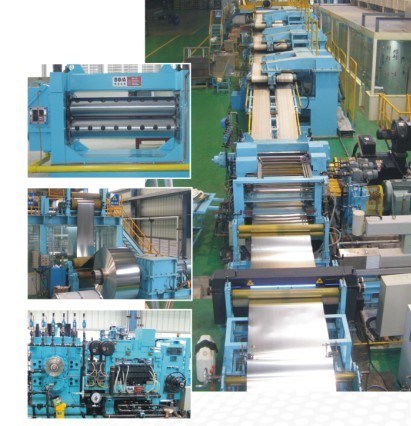

Cut to Length Line Working Pictures

Cut to Length Line Quality and After-sell Service

1,Within>

DEVIATION-CORRECTING SYSTEM

Inquire

Other Products