Basic Info

Basic Info Model NO.: HJ-4

Product Description

China Cut-to -Length Line for Transformer Lamination (2-Shear & 3-Punch) Hj-400-5

Basic Info

Model NO.: HJ-400-5Product Description

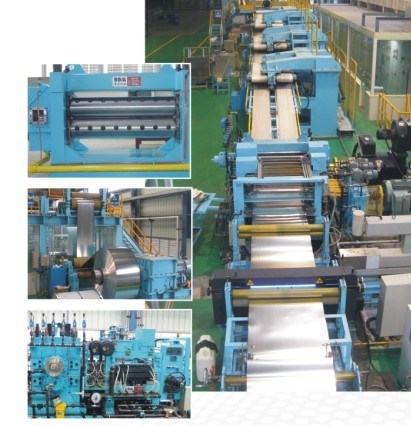

Application:The equipment is an ideal machining equipment for producing transformer silicon steel sheets, and the most advanced equipment in China developed by us independently with reference to the cut-to-length lines of Germany Georg and Belgium Soenen.

Components:

- Double-head Decoiler (auto-expansion, inverter control, auto-loading)

- Non-pit Buffer Device (Multistage speed automatic control, deceleration operation stable )

- Servo transfer billet system ( Full-closed-loop-control high accuracy)

- V type Punch Unit (Servo driven, able to longitudingal & cross step-lap mechanism.

- 45癝hearing unit (with servo motor)

- 135?shearing unit ( Servo drive center positioning)

- O type Punch Unit ( Servo drive center positioning, longitudinal auto move )

- Material stacking (servo location, magnetic sucking)

- Discharge trolley (auto-moving, servo location)

- Sid-guiding rail system (center-location, auto width-adjusting)

- Control cabinet and Operation console

- Pneumatic system (cylinders, valve, etc

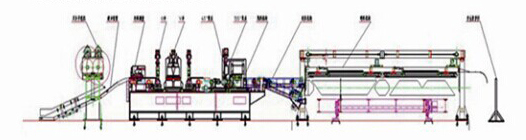

Process:

The equipment can be used for shearing, sorting, and stacking of silicon steel sheet iron cores automatically as required: With higher degree to automation, it can meet automatic production demand for machining transformer cores, ensuring product quality and machining accuracy. Automatic longitudinal movement is possible for punching to realize simultaneous operation of punching and shearing, thus production efficiency is increased. Automatic and accurate transverse positioning movement of the blanking tooling allows single shearing and automatic multiple shearing in a batch without frequent change of material, and accurate positioning via locating pin allows automatic column stacking function, thus reducing labor intensity of manual iron stacking greatly.

Main technical parameters:Parameter TypeHJ-400-5Coil material width tolerance?.1 mmShearing burr ≤0.02 mmS?deviationSingle direction ≤0.2 mm/2000 mmWidth of sheet40-440 mmLength of Sheet350-2000 mm (short side )Thickness of Sheet0.23-0.35 mmAccuracy in Length?0.2mm/2000 mmSheering burr≤0.02 mmLifetime of bladeApprox. Over 1.2 million cutsAccuracy of shearing angle?.025?/span>Max feeding speed0-240 m/minCutting time per time≤0.23 s (electrical)Punching mold burr≤0.02 mmLifetime of punching dieApprox 0.3-0.5 million punchesLayers of step-lap1,2,3,4,5,6,7,8Max stacking thickness450 mm (containing material board)Human-machine interfaceTouch screen soft keyboardSize of whole machine (L* W* H )18m * 5 m *2.2mInstallation capacity25 KW

STEEL SEWING MACHINE

Inquire

Inquire

Other Products