Basic Info

Basic Info Model NO.: JT12

Product Description

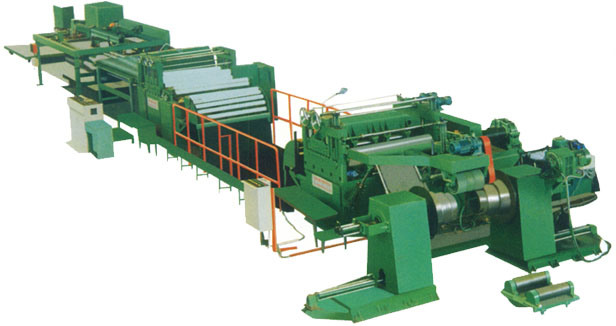

China Fully Automatic Transformer Core Cutting Line

Basic Info

Model NO.: JT1250 PLC: Mitsubishi, or Siemens Certificate: ISO9001 Warranty: 1 Year After-Sell Service: Yes Trademark: XIEER Transport Package: Seaworthy Packing Specification: 12.6*6.5m Origin: Jiangyin HS Code: 84623920Product Description

JT1250 Slitting LineSlitting Line Process Introduction

The JT1250 silicon steel (CRGO) slitting line , which cuts the coils of silicon steel strip into a certain width of the silicon steel strip, and then wind into the productive and productive and processing equipment according to a certain number of curly tension. It is widely used in food, packaging, building material, electrical and other metal processing industry.

Slitting Line Advantages

1,Adopts high steel high precision cutting machine and rolling machine, the designed deflection of the main system is>Slitting Line Equipment Composition

1) electric material feeding trolleyWith horizontal movement and lifting function,it is convenient to import the steel coils into the uncoiler clamping and fixing.Motor drive up and down,set 2 guide column device.Low speed motor drive level movement .Load capacity of coil weight: 5t(max)Function:used for lifting up and down,horizontal movement function,it is convenient to import the steel coil into the winder,the lifting platform adopts motor drive,the horizontal movement is driven by motor. The car is controlled in the ford control station.After the steel coil is fixed>2) hydraulic harmomegathus material rack

Support coil and uncoiling,max load capacity 5tThe hydraulic cylinder has a tight structure and supports the inner hole of the steel .The inverter brake motor drives the steel roll,the motor has positive and reverse function,prevent coil inertia rolling.Mechanical structure:steel plate and section steel welding and processing.Function:Fix the coil and uncoiling. cart put the steel coil straight to the center of uncoiler, the hydraulic pressure expander is driven by the hydraulic push of the core shaft.When the coiler is open,the coiler is driven by the motor. At run time,aautomatic uniformrelease roll.

Support coil and uncoiling,max load capacity 5tThe hydraulic cylinder has a tight structure and supports the inner hole of the steel .The inverter brake motor drives the steel roll,the motor has positive and reverse function,prevent coil inertia rolling.Mechanical structure:steel plate and section steel welding and processing.Function:Fix the coil and uncoiling. cart put the steel coil straight to the center of uncoiler, the hydraulic pressure expander is driven by the hydraulic push of the core shaft.When the coiler is open,the coiler is driven by the motor. At run time,aautomatic uniformrelease roll.3) buffer pit

Function:the buffer pit guide is made up of welded frame,which is used to undertake the sheet steel of uncoiler, to pass through the surface of the pattern plate, it won't scratch>4) material picking deviceTwo cylinders lift up and down,control cylinder complete action knob.The guide plate is controlled by manual reversing valve to control the cylinder.Function:the feeding device is used to carry out the sheet that is released by the coiler to pass through the rotating cylinder surface,sucessfully enter the guiding device and slitting line. The feeding device is composed of a welded frame,and air cylinder control material and a guide plate.

5) activity guide deviceThe center line of the vertical production line moves in a horizontal direction along the longitudinal shear host bed.Function: the guide device can guide the silicon steel strip to smooth into the slitting machine and guide the shear of the silicon steel strip.

6) slitting line main machine

The slitting line main machine is composed of bed, speed reducer,overrunning clutch,spindle,cutter,bearing seat and so>The slitting line main machine can be installed with self-locking knife,three-point knife,set knife.The axis of knife shaft is 125-110 adjustable,easy to operate and increase the service life of the cutter.

The slitting line main machine is composed of bed, speed reducer,overrunning clutch,spindle,cutter,bearing seat and so>The slitting line main machine can be installed with self-locking knife,three-point knife,set knife.The axis of knife shaft is 125-110 adjustable,easy to operate and increase the service life of the cutter.7) picking material intermediater bridge

Pneumatic control the lifting and falling of the material. The ultrasonic sensor detects the high and low position of the silicon steel belt to control the speed of the coil winding machine. The main function of the intermediate bridge is to bear the strip of steel after shearing,enter the tightening device, and the position of the strip is measured, and to control the rolling speed of the coiler.The intermediate bridge is composed of a frame,two cylinders,a drum,a material turning plate,a rotating arm,an ultrasonic sensor and so>8) expanding device

The slitting plate is used to isolate the uncoiling silicon steel,avoid overlap.Provide tension for coiling.

9) hydraulic harmomegathus rolling equipmentUse hydraulic pressure to retract the scroll,tighten the inner hole.Coiler max coiling diameter is 1200mmMechanical structure:steel plate and structural steel are welded and processing.Coiling the strips after slitting.

10) electric unloading cart

This cart load coils,mobile lift.

This cart load coils,mobile lift.11) hydraulic station and air system

Hydraulic station is the power source of oil system. The pneumatic system is the power source ,which provides the power for the cylinder of the production line.

12) electric cabinet and operation platform

PLC control,whole line automatically control and adjust.

13) drive motorUncoiler inverter electromagnetic brake three-phase asynchronous motor:7.5KWMaterial loading cart three-phase asynchronous motor:4KWMaterial unloading cart :4KWLow speed motor:0.3KW*2Rolling cutting machine frequency control three-phase asynchronous motor:7.5KWCoiler frequency control three-phase asynchronous motor:30KW

Parameters

1,Machine ParametersApplication MaterialSilicon Steel CoilCutting Material Thickness(mm)0.23-0.5Cutting Material Width(mm)40-1200Coil Inner Diameter(mm)500Coil Outer Diameter(mm)1200Coil Weight(t)5Cutting Speed(m/min)80-120Maximum Strips13Spindle Diameter(mm)125Slitting Cutting Blade MaterialYG15 40CrSlitting Cutting Blade HardnessHRA86.5Slitting Cutting Blade Density(g/cm3)13.9-14.2Whole Slitting Line Weight(t)20Slitting Cutting Blade Bending Strength(kg/mm2)210Slitting Line Speed(m/min)80-120Total Motor Power(KW)55Slitting Line Layout Squaremeter12.6*6.5Production Operator1-2Main Circuit Rated Input Current≤150ACabinet Temperature at Run Time(篊)0-40Environmental Humidity Requirement(40篊 temperature)0-85%, without condensationOperation Cabinet Size(L*W*H mm)1600*650*2000Slitting Line Machine ColorAs Customer Require

2,Slitting Line Finished Product ParametersStraightness Deviation of Each Edge(mm/m)?.1Cutting Angle Accuracy DEG?.025Strip Width Accuracy(mm)?.1Cutting Burr(mm)≤0.02

3,Slitting Line Associated Machines Parameters

High Speed High Precision Slitting LineModel NameJT1250Cutting Thickness(mm)0.23-0.5Cutting Width(mm)40-1200Coil Weight(t)5Feeding Speed(m/min)80-120Straightness Deviation of Each Edge(mm/m)0.1Cutting Angle Accuracy DEG?.025Band Width Accuracy(mm)?.1Total Motor Power(KW)55

Precision high speed cut-to-length linenonstop cutting

Two cutting two punching(ordinary type)Model NameJTXE-LL-300JTXE-LL-400Cutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-30040-400Cutting Length(mm)350-9999350-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)1516.5

Two cutting two punching(step type)Model NameJTXE-LL-300ZJTXE-LL-400ZCutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-30040-400Cutting Length(mm)350-9999350-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)2021.5

Two cutting two punching(centralized positioning)Model NameJTXE-LL-400ZXJTXE-LL-600ZXCutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-40060-600Cutting Length(mm)350-9999350-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)2426

Center Post Silicon Steel Cut to Length Line(step type)Model NameJTXE-ZZ-300ZJTXE-ZZ-400ZCutting Thickness(mm)0.23-0.350.23-0.35Cutting Width(mm)40-30040-400Cutting Length(mm)150-9999150-9999Feeding Speed(m/min)180180Cutting Burr(mm)≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025Cutting Length Accuracy(mm)?.1?.1Total Motor Power(KW)1414

Precision high speed cut-to-length line nonstop cutting

Two cutting>Model NameJTXE-X-300JTXE-X-400JTXE-X-600Cutting Thickness(mm)0.23-0.350.23-0.350.23-0.35Cutting Width(mm)40-30040-40060-600Cutting Length(mm)350-9999350-9999350-9999Feeding Speed(m/min)180180180Cutting Burr(mm)≤0.02≤0.02≤0.02Cutting Angle Accuracy DEG?.025?.025?.025Cutting Length Accuracy(mm)?.1?.1?.1Total Motor Power(KW)1213.513.5

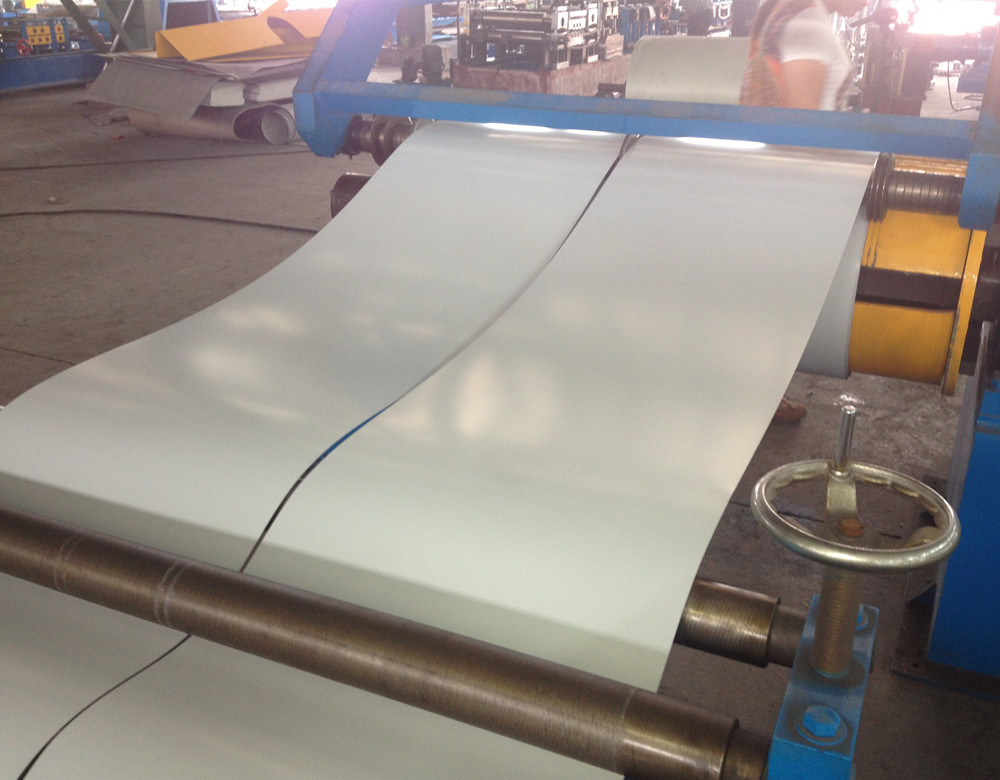

Slitting Line Working Process Picture

Slitting Line Certificate

Slitting Line Packaging

Closure strips

Inquire

Inquire

Other Products