Basic Info

Basic Info. Model NO.:Cut to Length Line Ty

Product Description

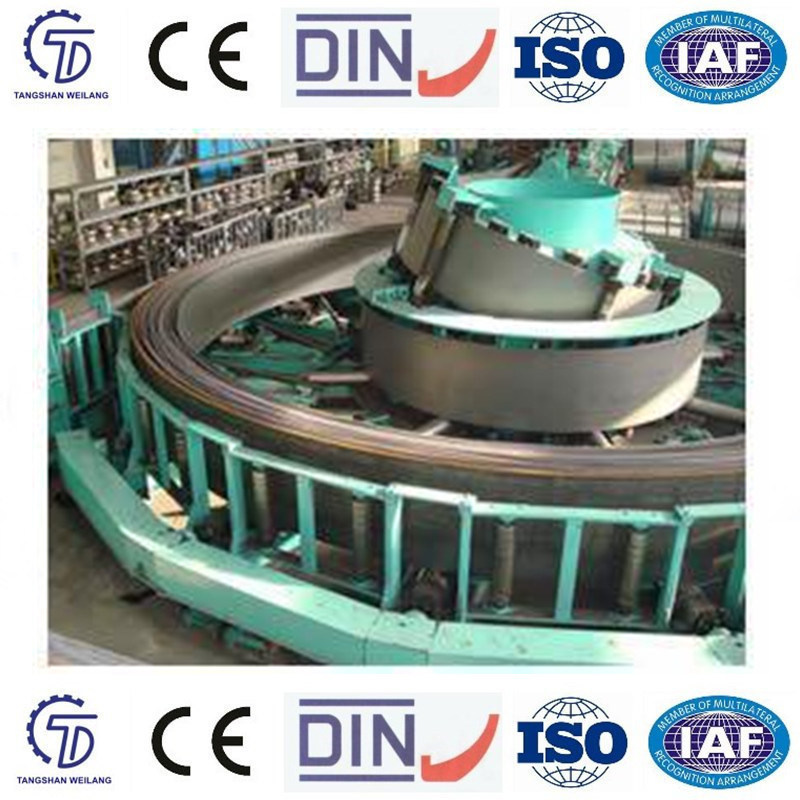

China High Speed Cut to Length Line

Basic Info.

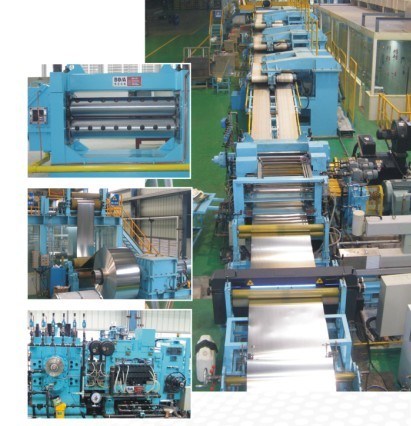

Model NO.:Cut to Length Line Type:Balance Roller Straightening Machine Usage:Sheet Voltage:220V Automatic Grade:Automatic Principle:Large Deformation Certification:CE Warranty:24 Months Customized:Non-Customized Condition:New Suitable Material:Colored Armor Plate Thickness of The Plate:0.3- 1.5mm Input Width of The Plate:1500 mm Control System:PLC Control System Productivity:15-25 M/Min Roller Material:45# Steel or Rubber Shafts Max Thickness of The Raw Material:3 mm Transmission Chain Is 25:25.4mm (13) Material of The Cutting Blade:Cr12 Trademark:Huantu machinery Specification:1000-2000mm Origin:China HS Code:8462312000Product Description

High Speed Cut to Length Line

Parameters of Rotary Shear

Model/ Items

Thickness (mm)

Width (mm)

Shearing Accuracy (mm)

Max. Line Speed m/min

Max. Cutting Speed (spm)

Coil Weight (ton)

2x650

0.2-2

100-650

?.3/1000mm

60

150

8

2x800

0.2-2

100-800

60

150

82x1300

0.3-2

400-1300

70

150

152x1600

0.3-2

400-1600

70

150

15

3x1600

0.4-3

400-1600

70

120

15

Components of lineNo.NameUnitQty1Feeding tableset12Main machine for levelingset13Control systemset14Hydraulic systemset15Post cutset1

Features of Cut to Length Line

1. Our cut to length line uses a roll feeding, AC servo drive.

2. It has a fully digital length control system that ensures fast positioning with little error.

3. It has a hard chrome plated surface and is durable and abrasion resistant.

4. It is used together with a hydraulic shear or an air-clutch shear to carry out fast shearing and convenient clearance adjustment.

5. Our cut to length line is suitable for hot rolling carbon steel, tinplate, stainless steel, and other kinds of metals with coated surfaces.

6. High degree of automation, easy & reliable operation

7. High length precision, high sheet flatness

8. Good order stacking

Work Process

Turbine ventilators