Basic Info

Basic Info Model NO.: XY40

Product Description

China Ce Standard Three Roll Rubber Calender/Calending Mill

Basic Info

Model NO.: XY400X1400 Reducer: Hardened Gear Teeth,After Heat Treatment Lubrication: Oil or Grease Automatic Trademark: CX Transport Package: in Wooden Case Safety Packing Specification: ISO9001, SGS, CE Origin: China HS Code: 8477800000Product Description

Ce Standard Three Roll Rubber Calender/calending MillRubber Sheet Calendering Machine, Rubber Calendering Machine XY-230x630

DETAILED INTRODUCTION:

1. Working Conditions

1.1 Rubber Calendering machine Working Environment: temperature 7~40篊, maximum relative humidity 95%.

1.2 Power: Power: 380V 50HZ 3 phases

Compressed Air:0.6~0.8MPa

Cooling Water Pressure:0.4MPa

2. Rubber Calender Structure Specification

2.1 Body

(1) Body frame: Welded into shape, after annealing, overall processed through precise machine tool, high rigidity, not easy becoming deformed, smooth, wear-resisting.

(2) Base: Welded base, after annealing and machining, high rigidity, won't deform easily.

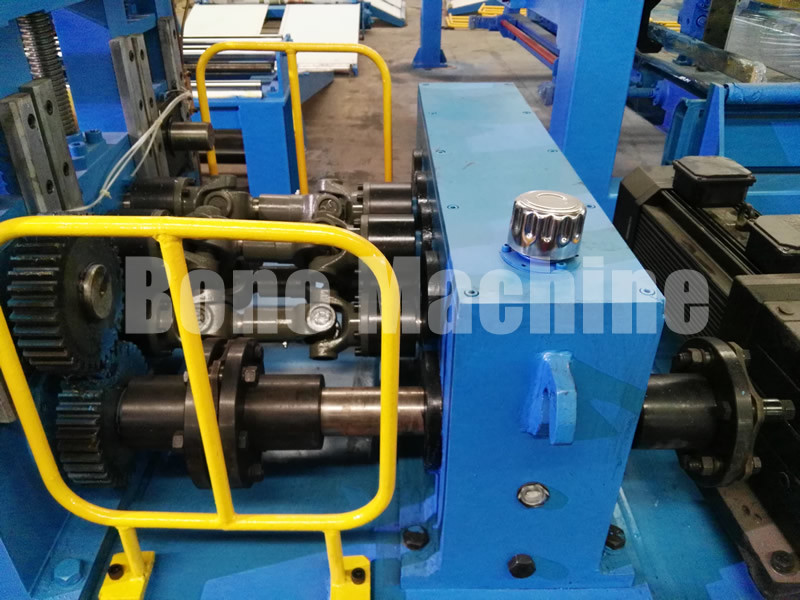

2.2 Rolls and Bearing Group

(1) Roll Structure: hollow smooth rolls

(2) Material: Alloy cold harden cast iron LTH-H

(3) Hardness:68-72HSD

(4) Cold Harden Layer:10-25mm

(5) Main Bearing: cylindrical roller bearings (Wafangdian Metallurgy Bearing)

(6) Bearing seats adopts cast iron (FC30), made from tempering handling. Excellent intensity and precision, together with lubrication oil holes. The bearing seats are made of aluminum with labyrinth ring oil seals to keep from oil leaking of inside and outside.

(7) Rolls nip has max. nip protecting function.

(8) Rolls temperature adjusting adopts high quality revolving joint and stainless metal pipe.

2.3 Nip Adjustment Device

(1) Adjusting Speed:3.6mm/min

(2) Motor Driving Power:1.5KW

2.4 Drive Mode

Adopts: driving motor reducer→stick coupler→driving gears →rolls rotating.

2.5 Reducer

(1) Type:one motor input,>2.6 Main Motor

Main motor adopts inverter motor, through frequency converter adjusting motor rotating speed.

2.7 Lubrication System

(1) Bearing Lubrication: the whole system contains a oil tank, including flow adjustment, oil table, cooler, filter and so>2.8 Stop guider group

2.8.1 Mode:axial moving type

2.8.2 This part adopts high quality SS41 steel welding, contact parts with the roller using MC nylon products, manual axial movement to adjust the spacing

2.9 Emergency braking equipment

2.9.1 Mode: Electro-hydraulic block brake.

2.9.2 Brake Capability: After braking roller skating for≤ 1/4 circumference.

2.9.3 Tight setting button installing equipment: in the left and right, front and back installed with mushroom mode tight buttons.

2.10 Electrical control group

2.10.1 Control cabinet: Surface paint floor type.

2.10.2 Operating Box: Operation control circuit.

2.10.3 Before leaving factory, manufacturer is responsible for connecting all the wires from controlling box to operation box, the useronly needs to connect the outside wire to the controlling box.

LIGHTSPOT:

1. 20 years>CERTIFICATE:

Qingdao Create Trust Industry Co., Ltd is the professional manufacturer of various rubber calender machines. Our company has passed ISO9001: 2008 Quality Management System Certification and our products have qualified with Sweden SGS Certificate, and CE Certificate.

Rubber Calender Technical Parameters:XY Three Roll

Model ItemXY-3I 630

XY-3L 630

XY-3630XY-3I 1120A

XY-3 1120A

XY-3L 1120AXY-3I 1400XY-3I 1500XY-3I 1730XY-3I 2130XY-3I 2430Roll diametermm230360400450610710810Roll working lengthmm630112014001500173021302430

Roll ratio 1:1:1

1:1.42:11:1:1

0.733:1:1

0.733:1:0.7331:1:1

1:1.383:1.383

1:1.383:11:1:1

1:1.5:11:1:1

1:1.4:11:1:11:1:1

1:1.5:1Middle roll speedr/min0.8-83-21.063-26.392.62-26.25.4-548-502-20Adjusting nip rangemm0-70-100-100-60-200-200.5-25Min.Calendering product thicknessmm0.20.20.20.20.150.150.5Calendering product widthmm100-500500-12001400140019002150Motor powerkW7.5455575132185220Overall dimensionsmm3168555065007420701076509300mm890164015002200395045603150mm1830212024402900373040805200About weightt~2.6~11~22~26~52~67~94

Our Services

Our engineers can design target machines for customers and send them the drawing to confirm. We are always srcid= ' 54908152 ' src= ' /upLoad/et29978302149352.jpg ' width= ' 720px ' />

FAQ

1. Delivery time of the rubber machines?

This is specially designed machine according to your specific requirement.

From engineer designing to production completion, it needs about 25 to 35 days.

2. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production.

Every machine will be fully assembled and carefully tested before shipment.

3. What's the machine quality guarantee?

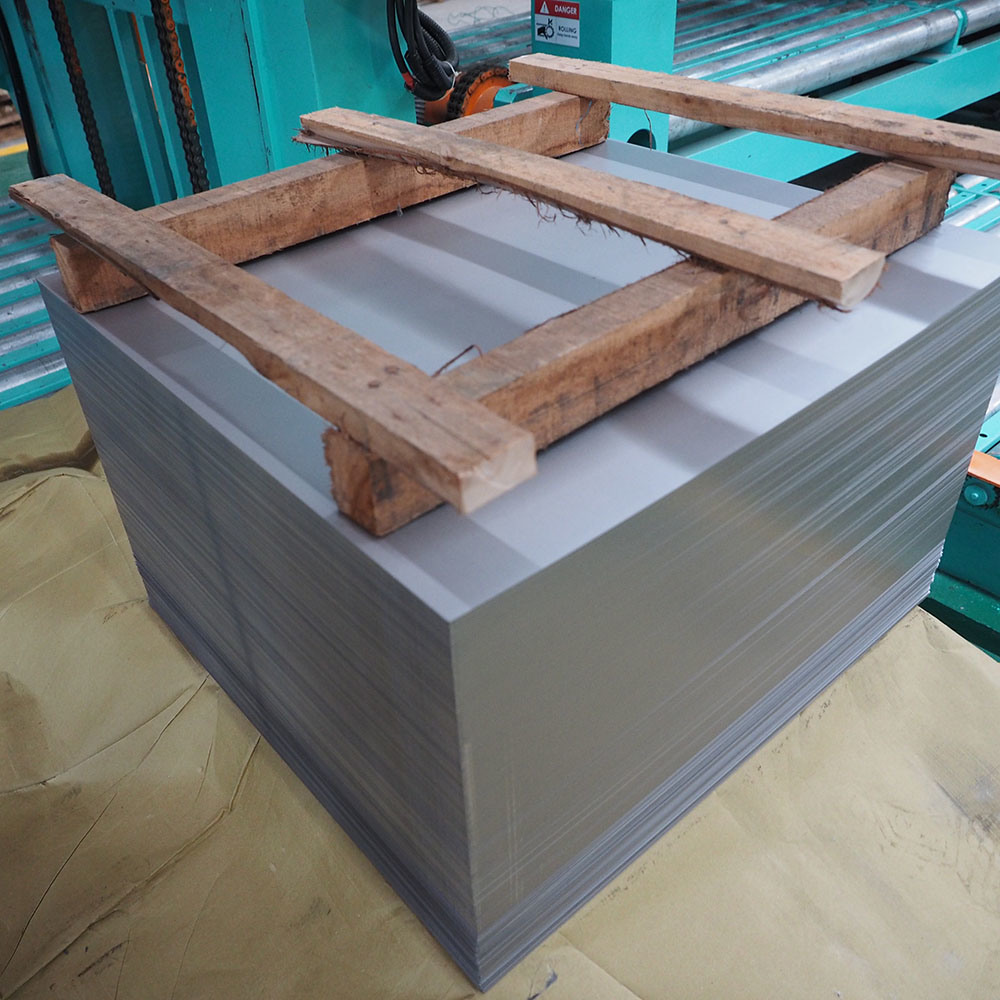

Quality guarantee time is>Packaging

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

There are 15 experienced engineers and 108 skilled workers in our company, guaranteeing delivery>

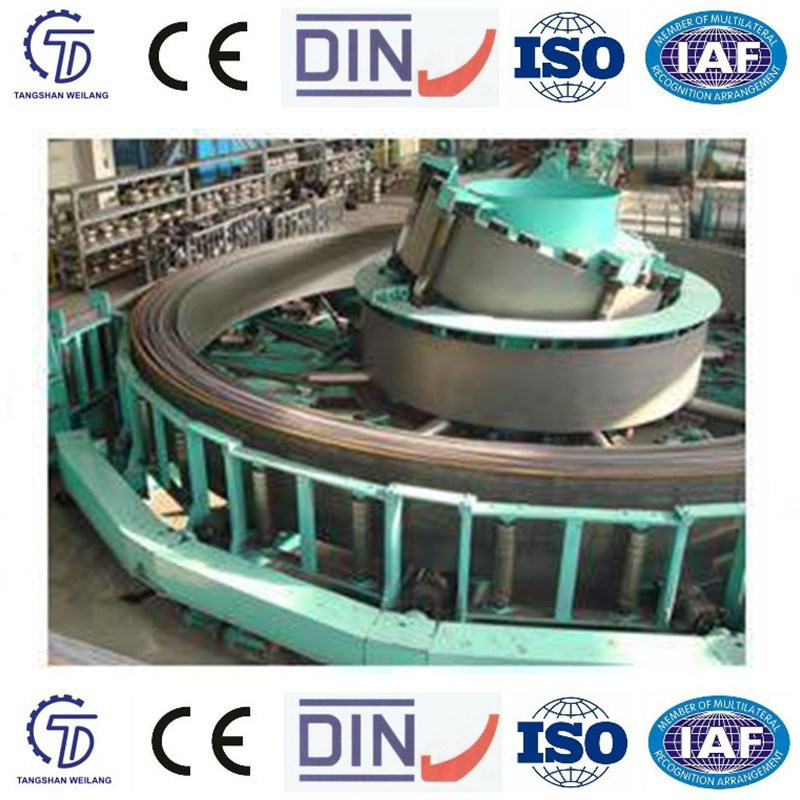

DEVIATION-CORRECTING SYSTEM

Inquire

Inquire

Other Products