Basic Info

Basic Info Product Description

Product Description

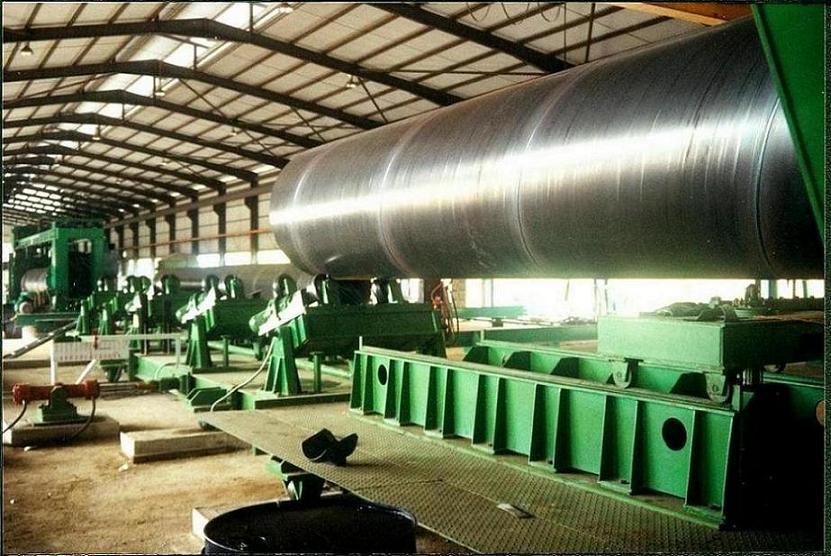

China SSAW Pipe Making Machine/ Spiral Pipe Making Machine (LH-2500)

Basic Info

Product Description

- Model NO.: LH-2500

- Certification: CE

Type: Pipe Mill

Pipe Material: Carbon Steel

Application: Energy Supply Pipe

Place of Origin: Shanxi, China (Mainland)

Brand Name: HUAYE

Model Number: LH-2500

Voltage: Design as per voltage of destination plant

Weight: Up to equipment configuration and process design

Certification: CE certificate

Warranty: 1 year's guarantee

After-sales Service Provided: Engineers available to service machinery overseas

Pipe diameter: 508-2540mm

Material grade: Carbon steel, up to X80

Plate thickness: 5-25.4mm

Plate width: 1200-2000mm

Coil weight: As per requirement

Equipment area: Arrange as per user's plant size

Certificate: CE, ISO

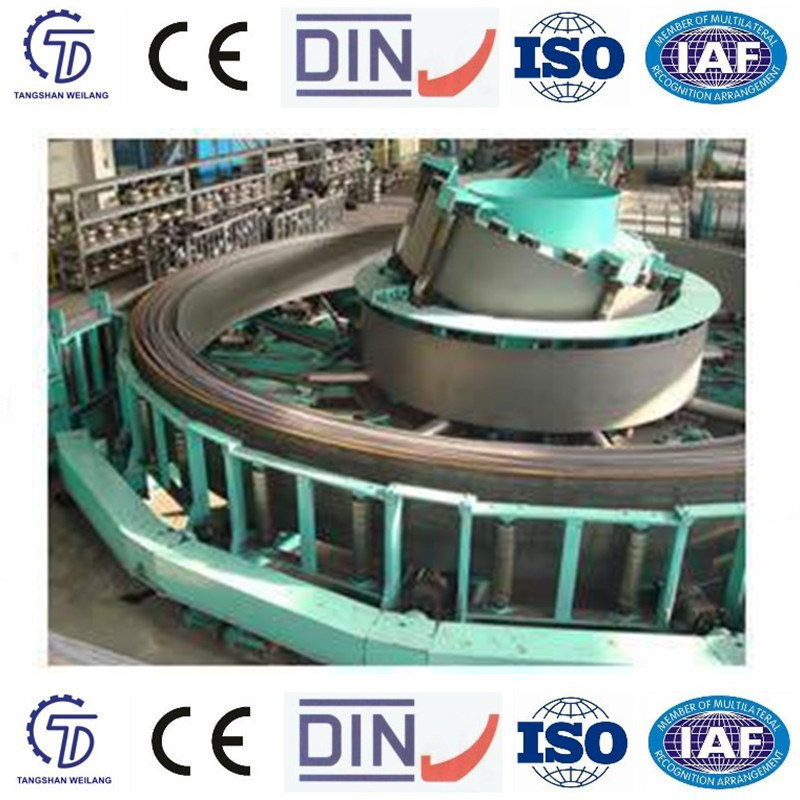

PLC control, high efficient, easy operation. Three roll-bend, outside control roll sizing, pipe meet with API 5L, GHOST, etc.

This pipe mill is used to process the strip into required spiral steel pipe in line with relative national standard by going through uncoling, leveling, edge shearing, forming and welding. Pipe produced can be used in different industries like low-pressure fluid transportation, gas pipeline, electric& heat power pipe network, industrial and construction.

Pipe usage:

1) high strength pertoleum& natural gas transportation pipeline;

2) low pressure liquid transportation pipeline, city coal gas and water drainage pipe;

3) piling pipe for project construction;

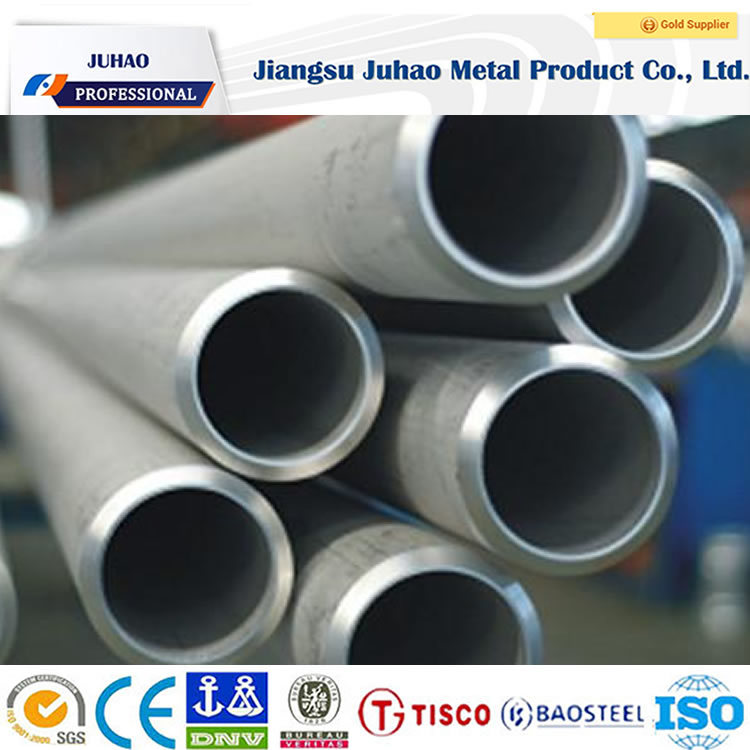

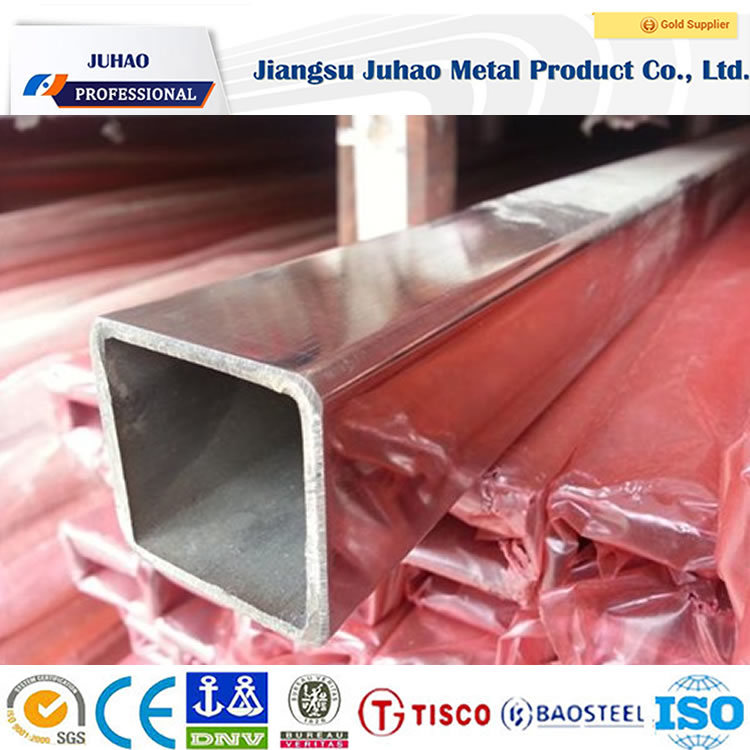

4) steel pipe for industrical structure;

5) other usages

Product quality:

Pipe product of this unit can meet with API-5L standard and GB/T3091-2001 standard.

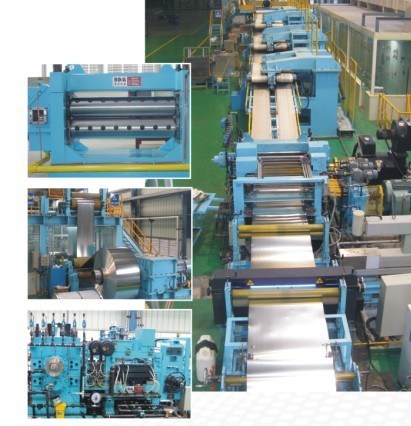

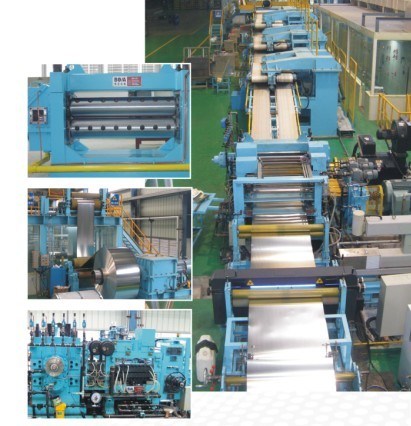

Process flow:

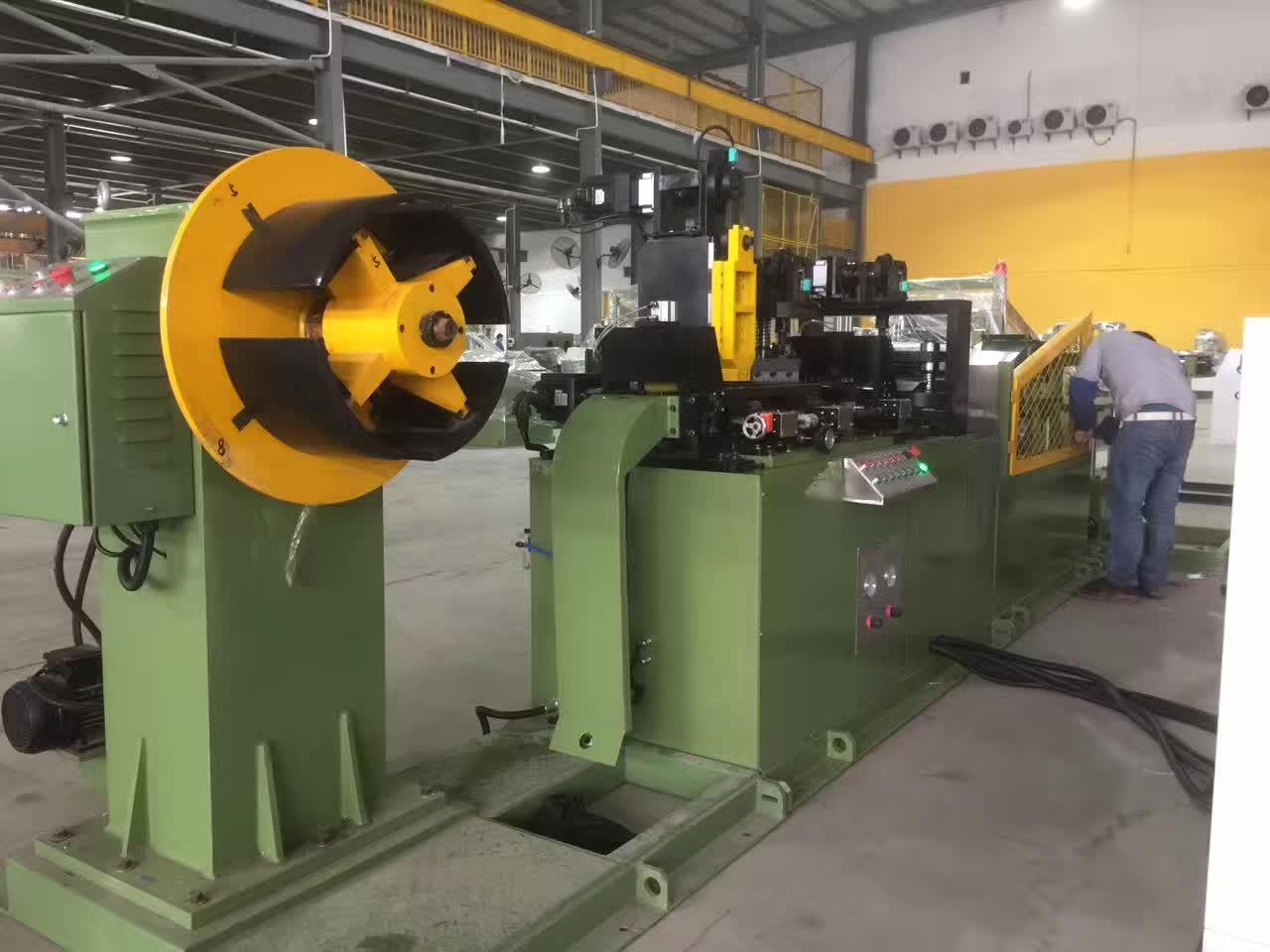

Uncoiling--pinching& leveling--electric vertical roll--cutting& butt welding--electric vertical roll--rotary shear--vertical roll--delivery m/c--guide board--forming unit--inside welding--outside welding--flying cutting--pulling out

Annual output:

(three shifts) 25, 000~40, 000T

Finishing section of spiral welded pipe, including pipe beveling machine, hdrostatic testing equipment, X ray& Ut flaw detection, as well as pipe weighing and marking device are optional and will be designed as per pipe usage and international standard.

UNCOILER

Inquire

Inquire

Other Products