Basic Info

Basic Info Model NO.: SL

Product Description

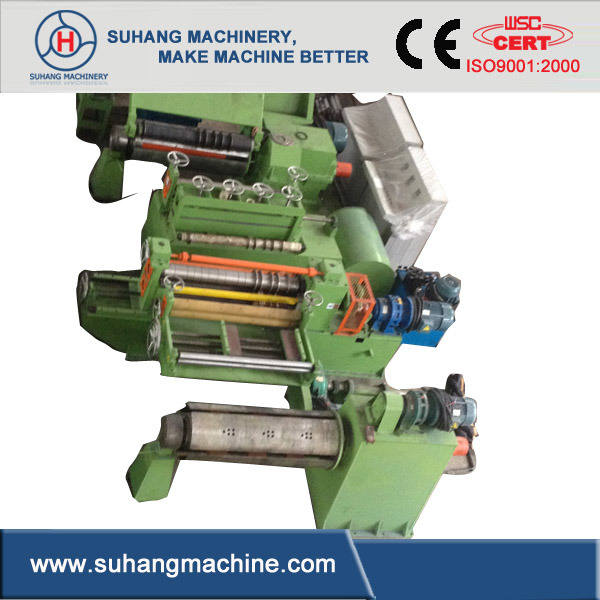

China High Speed Steel Slitting Production Line

Basic Info

Model NO.: SL Weight: 10ton Warranty: 1 Year After-Sales Service Provided: Engineers Available to Service Machinery Overseas Trademark: Suhang Specification: CE. SGS. ISO9001 Origin: Wuxi, Jiangsu HS Code: 8455229090Product Description

Steel Slitting LineThis machine adopts Seven Rolls level correction, roll arbors adopt high-quality alloyed steel 40Cr, made with a heat treatment, and it has a perfect effectiveness of level correction to defect band steel;

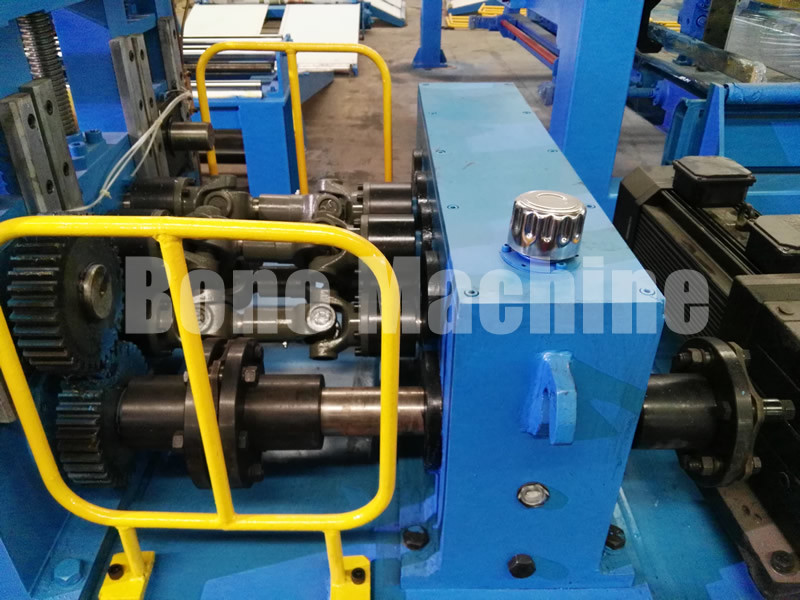

The roller of the principal machine adopts the bearing steel Cr15 to strike, distressing to annealing, quenching, tempering, and Parkerizing, such heat treatment process. The surface hardness reached HRC60 degree. All the rollers are made by the numerical control lather, and this guarantees the accuracy of the roller's sizes and prolongs its working life.

TRANSPORTATION

All goods will be shipped to your country, containers number will be decided with how many machines would you choose

Installation of the machine

The individual components of the machine are installed according to the layout and prepared for the commissioning.

The installation comprises of:

- Installation by Suhang service technicians.

- The following services are included:

- Installation of the machine components.

- Adjustment of the machine components.

- Connection of all motors to the control cabinet.

- Installation of the required safety devices.

Delivery extent does not comprise of:

- Media supply (electrics, etc. )to the machine(control cabinet)

- Raw material, process material

- Raw material for test

- Transport and lifting devices

- Auxiliary staff.

The operators of the plant should be present during the installation in order to become familiar with the new machines. Number Items Unit\Type RF-SM 1 Production Speed m/min 5-10 2 Steel Thickness mm 0.4-1.2 3 Material of the roller Cr15 4 Rolling width mm 1200 5 Electric power kw 3 6 Hydraulic cut power kw 3 7 Control system Industrial PLC to control by frequency conversion

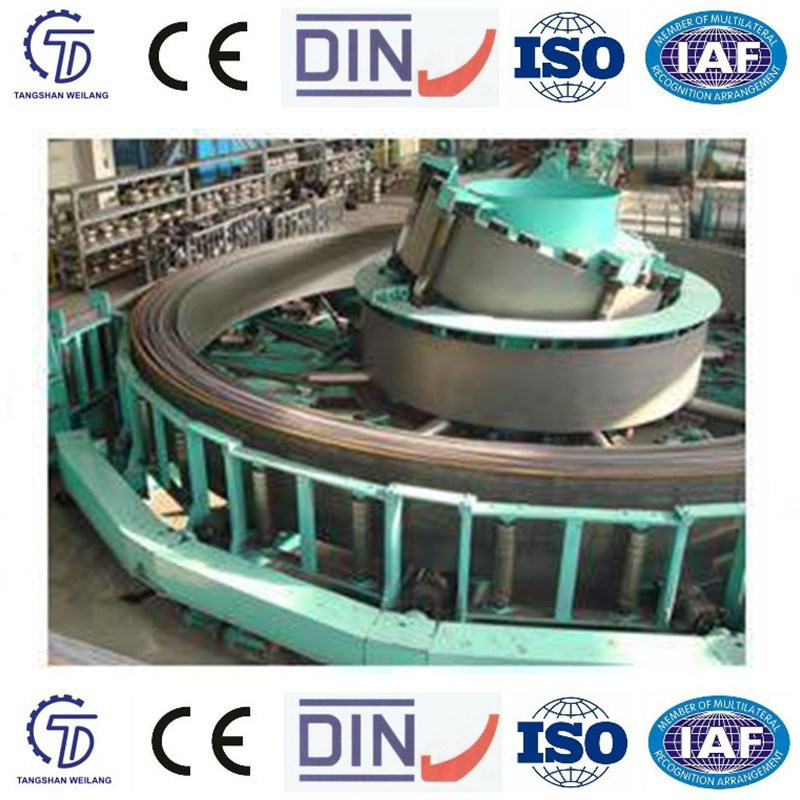

PATTERN PPGI/PPGL PRODUCTION LINE

Inquire

Inquire

Other Products