Basic Info

Basic Info Product Description

Product Description

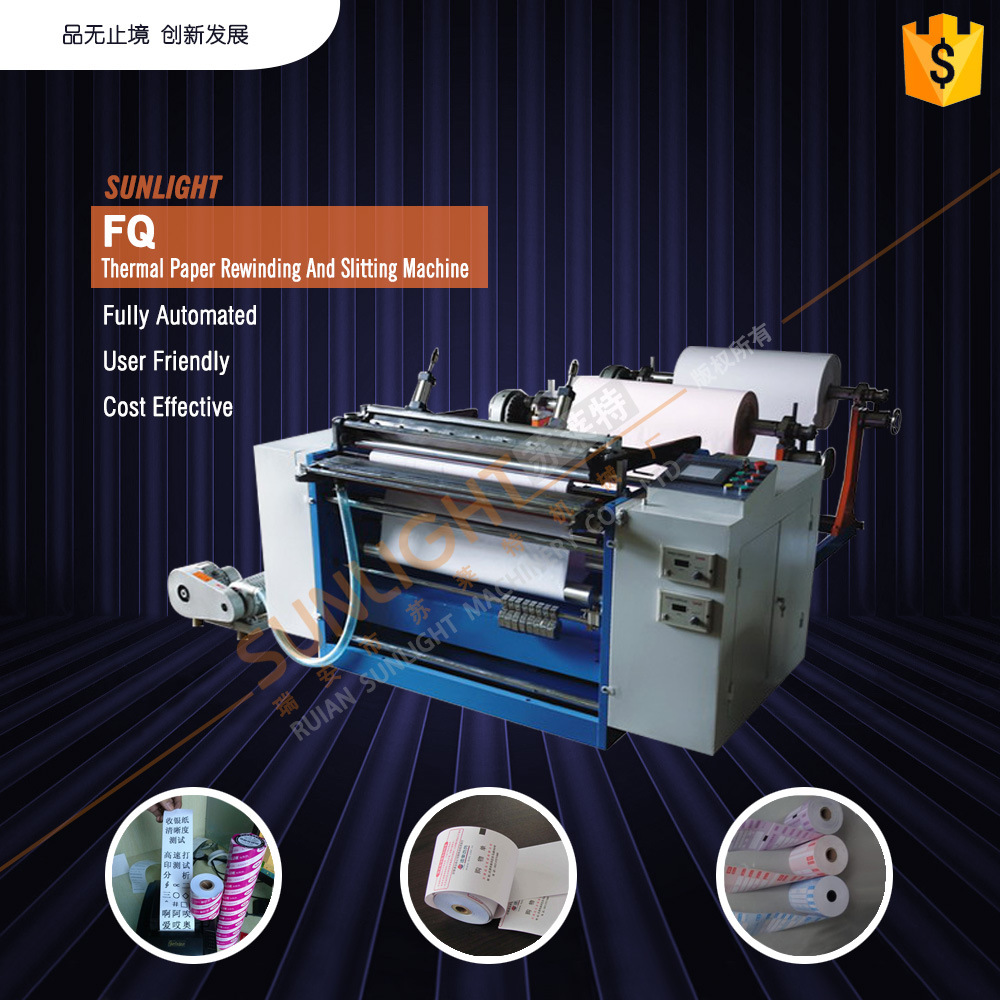

China High Speed Thermal Paper Slitting Line (FQ-900)

Basic Info

Product Description

- Model NO.: FQ-900

- Type: Slitting Rewinder

- Structure: Cutting Part

- Classification: Cloth Cutting Machine

- Suitable Substrates: Paper

- Slitting Type: Knife Slit

- Function: Converter

- Motor Control: Inverter

- Speed: 0-150m/Min

- Operator: 1 Person

- Trademark: SUNLIGHT

- Origin: China

- Application: Commodity

- Work Method: Round Knife Cutting

- Packaging: Case

- Applicable Process: Process Materials

- Packaging Material: Paper

- Material: Film , Paper , Foil

- Control System: PLC

- Cutting System: Circle Knife

- Tension Control: Frequency Motor

- Voltage: 380V, 3phase ,50Hz ,or According Client Requiremen

- Specification: 900mm width

- HS Code: 844110000

If you want see more information of our machine

Pls check Our website: www.sltmachinery.com

Give us five minutes and we'll suggest you some good ideas!

Our Factory Produce Paper Tube Machine, Slitting Rewinding Machine, Film Blowing Machine, Printing Machine, Bag Making Machine. Etc

Pls check the video and spec in our website

FQ Thermal Paper Slitter Rewinder With Lift System

Http: //www.sltmachinery.com/product_show. Aspx? Id=195

Specification

Use:

Thermal Fax Paper Slitter Rewinder is suitable for slitting and rewinding record paper such as fax paper, computer print paper, electro-cardiogram printing paper, cash register roll paper, ATM paper, POS paper roll, etc.

Feature:

Unwinding Shaft: 3 ' Air Expanding Shaft with magnetic powder brake

Automatic tension controller

Rewinding Shaft: 12.7mm onwards or you can choose your shaft

Siemens PLC and Weinview touch screen made in TAIWAN

Frequency inverter motor

Emergency switch

Red Line Marker which is used to make a red line to remind the paper roll near to the end

Disc type blade for material slitting

Automatic meter counter which will stop the machine when reach the pre-set length

Synchronic belt to avoid the overlap problem

Air blower and expulsion tube for Trimmed waste

Automatic Life system for unwinder

Advantage:

Easy to install, easy to learn,

Strong physical construction

Quick delivery time.

Service Questions and Answers

Installation:

For clients who purchase our machines for the first time, we will assign engineers to buyer's factory, within appointed time, to install the machines and train the operators for buyer. Engineer's wages and transportation expenses from our factory to the domestic airport is on our account.

During installation period, clients should offer accommodation, round-trip tickets, visa expenses for our engineers. Eight hours working time per day.

Warranty

1. Warranty Time: 12 months;

2. The company regards clients as gods. A replacement can be made after the confirmation made by our relevant department when accessories breakdown under the condition of right use within warranty period. The company develops archive for every single machine that is made. Serial numbers are marked on each machine part and archived. It's pretty convenient for our clients to change spare parts when necessary. The only thing you need to do is to provide us the serial numbers on the spare parts, which need to be replaced. Moreover, we provide one year warranty after sale. We offer free spare parts within the warranty time, except damages caused by human factors and irresistible external factors.

3. If buyers damaged any parts of the machine without abiding by the using condition, using environment and usage that the instruction manual demanded within warranty time, we will only provide paid services under this circumstances.

4. There will be an operation training for operator: (1) Training for right operation; (2) Training for common sense of daily maintenance; (3) Introducing after-sale services and training for solutions; (4) Introducing after-sale services and notify the contact way; Accessories supply guarantee: We supply free accessories within one year warranty period. We will charge you for accessories supply when the warranty is overdue;

5. We offer 24 hours after-sale consulting services nationwide on hotline;

6. Video solution of equipment emergency failure. User themselves need to equip video system and devices. Our technicians will analyze the problems through video and guide clients' technician to solve the problem all together.

7. FAQ online is available.Production Capacity:Product NameProduction Line CapacityActual Units Produced ( Previous Year )

Slitter Rewinder10 Sets / Month;8 Sets

Export Market Distribution:MarketRevenue ( Previous Year )Total Revenue (%)

North Americaconfidential1

South Americaconfidential1

Eastern Europeconfidential4

Southeast Asiaconfidential5

Africaconfidential30

Oceaniaconfidential2

Mid Eastconfidential30

Eastern Asiaconfidential3

Western Europeconfidential2

Central Americaconfidential3

Northern Europeconfidential1

Southern Europeconfidential1

South Asiaconfidential16

Domestic Marketconfidential1

Production Machinery:Machine NameBrand & Model No.QuantityNumber of Year(s) UsedConditionLatheCA6140A22.0AcceptableMilling machineNo information25.0AcceptableRadial drilling machineZ3050*16A24.0AcceptableWelding machineNB-31535.0AcceptablePlate shearing machineNo information13.0AcceptableOxygen welding and cutting machineNo information15.0AcceptableBending machineNo information14.0AcceptableTesting Machinery:Machine NameBrand & Model No.QuantityNumber of Year(s) UsedConditionTensile testing machineQJ21013.0AcceptableReal Case for Lower MOQ:Products NameMOQ(in the last 12month)

Slitter Rewinder1 Set

Real Case for Large Contract:Products NameOrder(in the last 12month)

Slitter Rewinder5 Set

Short Lead Time:Products NameOrder(in the last 12month)Shortest Lead Time

Slitter Rewinder1 Set35 Days

Main technical parameter :ModelFQ-900

Max. slitting width:900mm

Max. unwinding diameter .:900 mm

Unwinding paper core diameter :76 mm

Slitting width:32mm, 35mm, 57mm, 210mm, 216mm, 257mm etc.

Max. Rewinding diameter :200-300 mm

Rewind paper core inner diameter .:0.5 inch, 1 inch or special size

Max slitting speed:180m/min

Total Power5kw

Voltage:380V, 50Hz, 3Phase

Weight:1700KG

PRECISE FOUR

Inquire

Inquire

Other Products