Basic Info

Basic Info

Product Description

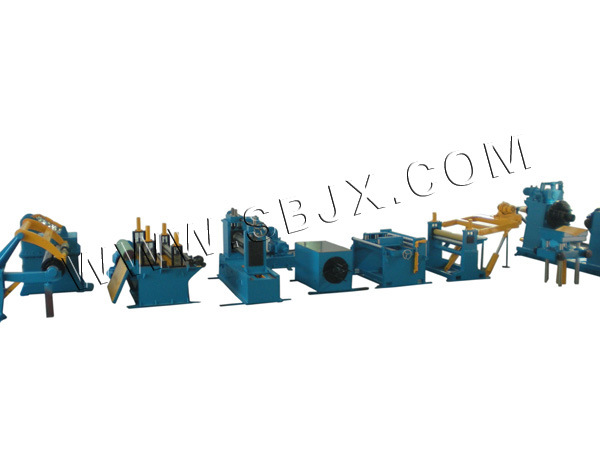

China Slitting and Cut to Length Line

- Model NO.: T44K

- Transport Package: Seaworthy Packing/Naked

- Origin: Jiangsu, China

- Trademark: SIECCTECH

- Specification: based>T44K Economic Cut-To-Length line

I,Main performance and usage

This production line structure is practical, reliable performance, convenient operation and maintenance, applicable to thickness 0.5--2mm, width below 1500mm used for uncoiling, leveling, fixed length cutting operation of the following specifications of Carbon steel coil, galvanized plate coil, etc.

II,Main technical data

Material: Carbon steel coil, galvanized plate coil, etc.

Strength: σs≤280Mpa,σb≤480Mpa

1,Processing thickness:0.5~2mm

2,Processing width:300~1500mm

3,Coil weight:8T

4,Inner dia. of coil:Φ508mm Φ610mm

Outer dia. of coil: Φ508mm~Φ1800mm;

5,Leveling speed:≤30m/min(adjustable)

5-12pcs/min(as 1000~2000mm sheet)

6,Leveling rollers number:11 rollers

7,Leveling rollers dia. :?/span>90mm

8,Leveling precision:≤?/span>2.0mm/m2 (as thickness 1.2mm)

Length precision: ≤?/span>1.5mm /2m

Diagonal precision: ≤?/span>1.0mm/2m

9,Cut-to-length range:300~4000mm

10,Stacking height: ≤650mm(include tool 150mm)

Stacking height: Max. 5000kg

11,Total power of equipment:60KW

12,Hydraulic system working pressure: ≤15MPa

13,Overall dimension of installation(L?/span>W):About 18500mm?/span>6000mm

Line composed by:

Feeding car→Uncoiler Hydraulic support→Stripping head straight head traction device (optional)→Hydraulic swing bridge and buffer storage pit→Correcting device→Main leveling machine→Shearing machine→Conveyor belt(optional)→Hydraulic lifting table(optional) stack device(optional)→Hydraulic system→Pneumatic system→Electrical control system

III,Main parts and brief description- Feeding car

2,Uncoiler

Adopts The cantilever type hydraulic inner expansion uncoiler.

Without power and passive loading.

There is dynamic pressure guiding device in the top of coil material.

3,Stripping head straight head traction device(optional):

Hydraulic telescopic feeding guide plate, telescopic lifting action. The motor in the hydraulic arm swing bracket expanse the coil material through reducer chain transmission drive the glue rollers.

The hydraulic cylinder drive the pressing- head do rise-down pressing in order to enter the traction roller.

4,Hydraulic swing bridge and buffer storage pit

The sheet go into the automatic scale feeding-straightening machine by swinging bridge, line downward swing

5,Correcting device:

To prevent the sheet left or right deviation, composed by bracket, adjusting screw and correcting wheel.

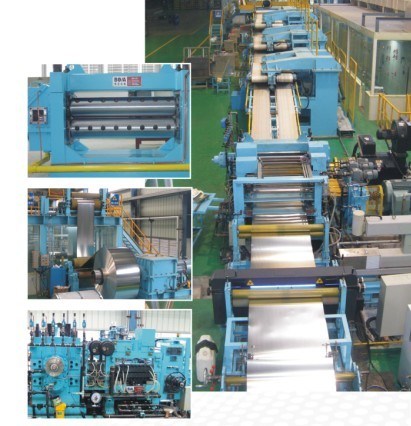

6,Main leveling machine

Leveling machine is four-high 11 rollers, with another 2 traction rollers, mainly composed of machine frame part, roller part, movable cross beam, pressing mechanism, main driving part, electrical control system, centralized lubrication system, digital display device and mechanical display, basic components etc. The material of leveling rollers is 42CrMo, quenching tempering-quenching after grinding, hardness HRC50 ~ 55. In order to ensure the work roller without radial and axial phenomenon, roller end with double rows of heavy mill bearing which connected with roller shaft seat.

8. Shearing machine

With 2x1500 mechanical shearing machine

9,Conveyor belt(optional)

The sheet after cut from the shear machine, take it backward transport to aggregate.

The motor drives the chain transmission belt frequency control synchronized with cutting and stamping material

10,stack device(optional)

Composed by pneumatic turn type monolithic frame, width and length adjusted structure(motor power(0.75Kw*3), pneumatic pusher type monolithic device, hydraulic lifting table, aggregate discharge car etc.

11,Hydraulic system

It is consists of hydraulic station, suitable valve, pipe, and cylinders.

4KW motor, 10L plunger pump, the highest pressure is 25Mp, the actual pressure≤15MP. Main hydraulic cylinder adopts imported seal rings, other accessories choose domestic high-quality goods.

12,Pneumatic system

Consists of gas processing triple parts, solenoid valve, pipe and cylinder etc.

Note: air source supplied by the user

13,Electrical control system

Electrical control system constitution

1). Input power supply control box (power): 1 piece

2) . Main control operation table : 1 piece

3). Auxiliary control box 1 piece

Programmable control system

Composed by programmable controller (PLC), touch screen, output isolation relay board and other components. PLC is the core part of the system, which controls the whole line's running, including the data collection, encoder data input, analog data acquisition, control output of each execution unit for each node position signal.

Using centralized control, consist of touch screen, PLC and AC frequency control. Cut length, shear number can be set by operating table control, computer control has two methods of work there are manual, automatic programming, in the automatic mode, the computer control of the whole cut-to-length process, in the control software, it design error

14,Other assistant device

Safety cover ,switch and foundation bolt are provided by supplier.

Ground pit and protection fence and equipment fence and trench cover are made in site.

Guide rail and others of equipment are prepared by user.

VI,Attached: list of some parts suppliers

1,Bearings China famous factor such as Ha,wa,luo factory;

2,Main electric elements Siemens(Suzhou);

3,Main reducer Jiangsu Taixing or Tailong;

4,Main motor Siemens(Beide);

5,Touched screen: Weinview(Taiwan brand made in China);

6,PLC Mistubishi(Japan brand);

7,Frequency: Delta(Taiwan brand);

8,Hydraulic Solenoid valve: China good quality and famous brand or Japan and Taiwan brand made in China ;

9,Main seal rings: Japanese Valqua or same grade imported brand

FAQHow about your machine quality?We are worry about the quality.

Brillante is a mature brand in CHINA,through our many years research in technology,our design including structure and detailed sercurity and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry ,there are Brillante machines.And where there are our machines,there are good reputation and terminal user satisfaction.

Whether the machine price can be more discount

Brillante always provide high quality machine,as we know ,oversea market is more important and difficult than domestic market because of communication time costing after sales,So always,our machine has enough qaulity standard to make sure the machine can work more than the real warranty period.In this way ,we will save a lot and think in advance for the clients.

Actually Brillante also think about our price level,we are sure to provide quality=price and pice=quality ,the matched price and acceptable for the clients and durable for our machines.We welcome your negotiate with us and get a good satisfaction.How about your manufactory in CHINA

Brillante located in HAIAN CITY,NANTONG,JIANGSU province who is the leading area in China and also in the worldwide as the center of the metal plate solution machines,We have worked about 10 years in this area and totally have about 150 staffs.Rich experience in this field with professional technical supporting and oriented service.

We welcome your visit to us any time.

Brillante provide oriented after-sales service including the oversea engineers trainning available and also international dealer center for any emergency guidance.We have established worldwide network to guarantee our timely response for your any demand no matter where are you.

We welcome engineers from your side to learn the technical design and normal maintenance here,this will help your easy in understanding and helpful if you need to be our dealer.

However,donto worry,we have our company own CD/Manual to show you along with the machine.So you can learn this from the existing docments to deepen your knowledge and understanding.

Anyhow there are another way is through internet video face to face for machine teaching, because of the high development in internet,the world has become smaller and you can easy cath us if any assistance needed.

Through all the ways,we will guarantee the service quality and ensure you will be well helped anytime anywhere.Shining Industrial Enterprise (China) Co., Ltd.

Shanghai, China

Manufacturer/FactoryGold Member Since 2013

Audited Supplier

- OEM/ODM Service

- Factory Tour

QC12y Series Hydraulic Guillotine Shear 6 *4000, Hot Sale Machine Shearing

Guillotine Shear, CNC Sheet Metal Cutting Machine Hydraulic Shearing Machine

hydraulic Swing Beam Shearing Machine QC12y-6X3200 China Manufacturer Guillotine Hydraulic Shear Machine

QC12y 6X32000 Metal Plate Shearing Machine with Estun Control System

Steel Metal CNC Guillotine Shearing Machine

Uncoiling Machine From Siecc

QC11y 6X4000 CNC Metal Plate Guillotine Cutting Machine

QC11y 6X2500 Hydraulic CNC Cut Machine with Delem Da310 Control System

QC11y Series QC11y 6X2500 Hydraulic Metal Palte Shearing Machine CNC Cutting Machine Delem Da310 Cutting Machine

QC11y 6X3200 Metal Plate Guillotine Shear Machine

Hydraulic Steel Metal Shearing Machine

QC12y Series Swing Beam Hydraulic Shearing Machine

Hydraulic Plate Shearing Machine with Germany Bosch Rexroth Hydraulic Valves

QC12k Hydraulic Guillotine Shearing Machine Price, Alibaba China Supplier CNC Cutting Machine

Hydraulic Swing Shearing Machine QC12y 6X3200 for The Use of Cutting Machine

CNC Hydraulic Stainless Steel Cutting Machine, Steel Plate Cutting Machine, Hydraulic Shearing Machine

QC12y 12/2500 Metal Plate CNC Guillotine Machine

QC11y Hydraulic Metal Plate Guillotine Shear Machine

QC11y Heavy Plate Hydraulic Guillotine Shear Machine

QC11y Series Hydraulic Metal Plate CNC Guillotine Shear Machine Product Groups

- UNCOILING

- MILLING MACHINE

- GRINDING MACHINE

-

ROTATOR

- HGK TYPE SELF-ADJUSTABLE ROTATOR

- HG TYPE ADJUSTABLE ROTATOR

- BAND SAW

-

DRILLING MACHINE

- ZK5150C DRILLING MACHINE

- Z5125A DRILLING MACHINE

- Z5140A DRILL MACHINE

- BENCH DRILLING MACHINE

- RADIUS DRILLING MACHINE

-

SHEARING MACHINE

- QC12Y SHEARING MACHINE

- QC11Y SHEARING MACHINE

- Q11D SHEARING MACHINE

- Others SHEARING MACHINE

-

ROLLING MACHINE

- W11S 3 ROLLER HYDRAULIC

- W11F 3 ROLL ASYMMETRICAL

- W11 3 ROLL PYRAMID MECHANICAL

- W12 4 ROLL BENDING

- Others ROLLING MACHINE

- PROFILE BENDING MACHINE

-

MACHINE TOOLS

- HS TYPE SHEAR MACHINE

- GS HAND SHEAR MACHINE

- Others MACHINE TOOLS

-

H BEAM MACHINE

- H BEAM FLANGE STRAIGHTENING MACHINE

- LHA TYPE PORTAL TYPE WELDING MACHINE

- H-BEAM ASSEMBLY MACHINE

- CNC MULTI-HEAD FLAME CUTTING MACHINE

- PLASMA CUTTING MACHINE

-

PIPE BENDING MACHINE

- SB10 CNC

- V-CUTTING MACHINE

-

FOLDING MACHINE

- HYDRAULIC FOLDING MACHINE

- MAGNETIC BENDER MACHINE

- Others FOLDING MACHINE

-

LATHE MACHINE

- CQ6236B LATHE MACHINE

- CHB LATHE MACHINE

- CH LATHE MACHINE

- Others LATHE MACHINE

- HYDARULIC PRESS BRAKE(CNC/NC)

- CORNER NOTCHER

-

PUNCH MACHINE

- TURRET PUNCHING MACHINE

- HYDRAULIC PUNCH MACHINE

- IRONWORKER

- HYDRAULIC PRESS MACHIE

PATTERN ALUMINIUM COIL PRODUCTION LINEInquire