219-426mm Welded Pipe Mill/Welded Pipe Making Machine/Pipe Production Line Made in China (ZY-219)

-

If you have any enquiry about quotation or cooperation, please feel free to use the following enquiry form. Our sales representative will contact you within 24 hours. Thank you for your interest in our products.

Basic Info

Basic Info Product Description

Product Description

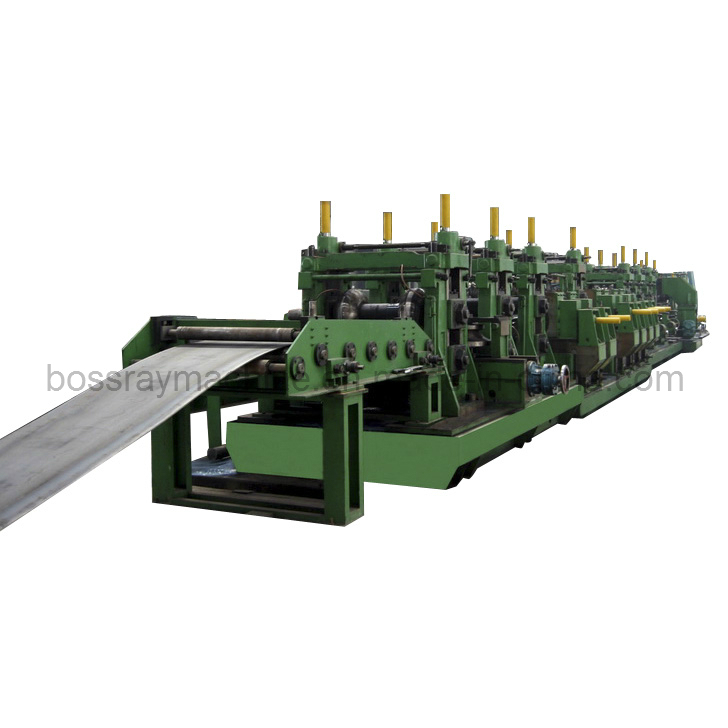

219-426mm Welded Pipe Mill/Welded Pipe Making Machine/Pipe Production Line Made in China (ZY-219)

Basic Info

Product Description

- Model NO.: ZY-219

- Servo Motor Drive Flying Cutting Saw: Option

- Shipping Port: Shanghai or Zhangjiagang

- Origin: Zhangjiagang, China

- Certification: CE

- Hydraulic Uncoiler: Option

- Trademark: BOSSRAY

- HS Code: 85152110

Pipe making machinery:

1. Pipe O. D: 89mm-219mm(3.5~ 8.6inch)

2. Square pipe: 70X70-170X170mm

3. Wall thickness: 4.0-8.0mm

ZY219 High-freqency straight seam Pipe making machinery:

1. Pipe O. D(round): 89mm-219mm(Φ3.5~ Φ8.6inch)

2. Square pipe: 70X70mm-170X170mm

3. Wall thickness: 4.0-8.0mm

4. Length: 4-12m

5. Speed: 0-50m/min

6. Main motor: 200Kwx2

7. H. F welder: 600Kw

Basic configuration: (May be changed according to customers' requirements)

Single-head uncoiler-(Straighten machine & Pinching & Levelling machine) -Shearing machine & CO2 Butt welding machine-Horizontal spiral accumulator group-Forming machine-High frequency induction welder-De-burr frame(Outside) -Seam grind unit-Cooling trough-Sizing mill-Turkey head-CNC flying saw-Run-out table

BOSSRAY Tube welding machine advantages:

1, Our tube welding machine adopts long term stabile machine bed which is ' machine bed tempering after welding to eliminate welding deformation stress in 48 hours ' , that other's manufacturer don't;

2, Machinery high alignment assembling based on ' the high-precision of assembling is ensured by CNC machining working accurance of parts ' , rather than tube welding mill machines assembled by relying on manual test assembly, cushion pading, looking for benchmark, welding positioning key;

3, Based upon deformation stress analysis, normally use double-driving, split-type main engine, our configuration will be 1 more set of DC drive motor, and 1 more main reduction than other factory's design;

4, The usage of higher drag motor power, then can achieve more higher production speed, and more broader products specifications;

5, Between main drive motor, reducer, points transmission case adot high strength and stable gear couplings;

6, Through deformation analysis, the quantity of roller frame configuration and roller is more, then will be more beneficial to stablize deformation, finally to obtain high quality welding and high precision dimensions;

7, Vertical and horizontal roller shaft bearing guard trim size design does not shrink, so bearing designation is bigger than other suppliers, and the front roller shaft frame are all used three stand (not two stand with space ring)joint bearing of heavy load design, and front and rear bearing end caps are designed with grease nipple fill, with seal protection;

8, Main machine vertical and horizontal roller stand all adopt copper alloy protection;

9, After welding, removaling outer burr, using standard horizontal rollers to polish welding seam, rather than simplifying to vertial roller frame;

10, Friction saw and Cold saw's drive more stable, lower resistance (even hand can easily push it).

TENSIONER

Inquire

Inquire

Other Products