Basic Info

Basic Info Model NO.: RH

Product Description

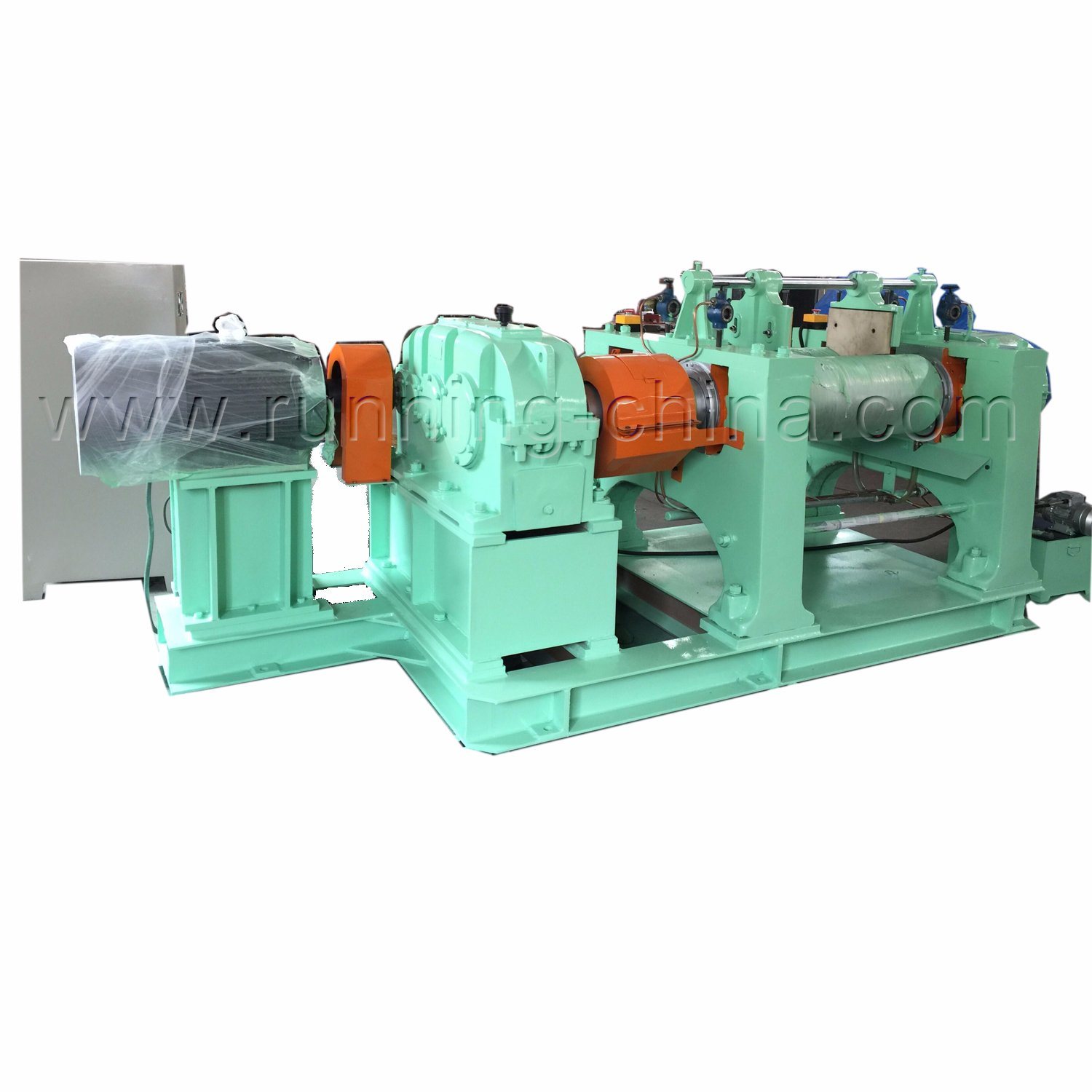

China Pipe Welding Line

Basic Info

Model NO.: RH HS Code: 84552210Product Description

1. Description of product1.1 Summary:

The composition of equipment is from uncoiler to fixed length cutting saw. Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness. This equipment is specially used for produce Φ8~Φ25mm, δ0.3~1.0mm high-frequency straight welded pipe and corresponding square pipe and special-shaped pipe (δ≤1.0mm).

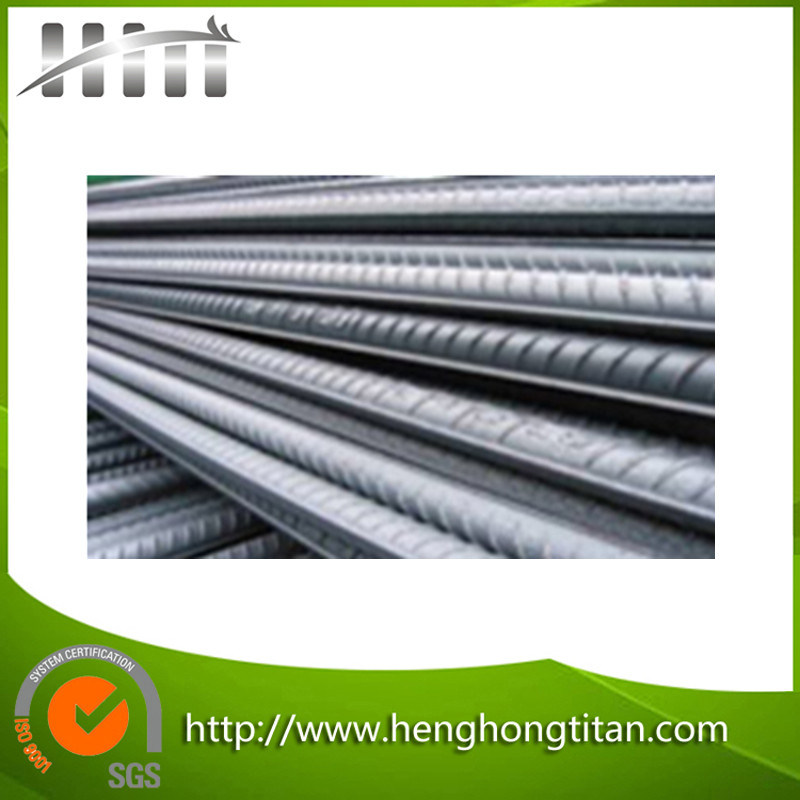

1.2 Applicable material:

(1)Hot or cold-rolled steel strip (As per GB700-88)

(2)Material: Low-carbon steel, low alloy steel

(3)The thickness of steel strip: 0.3-1.0mm (As per GB708-88)

(4)The width of steel strip: 25-80mm

(5)I.D. of steel coil: Φ350-Φ450mm

(6)O.D. of steel coil: Φ800-Φ1000mm

(7)Maximum weight coil: 800kgs

1.3 Dimension range of processing steel pipe:

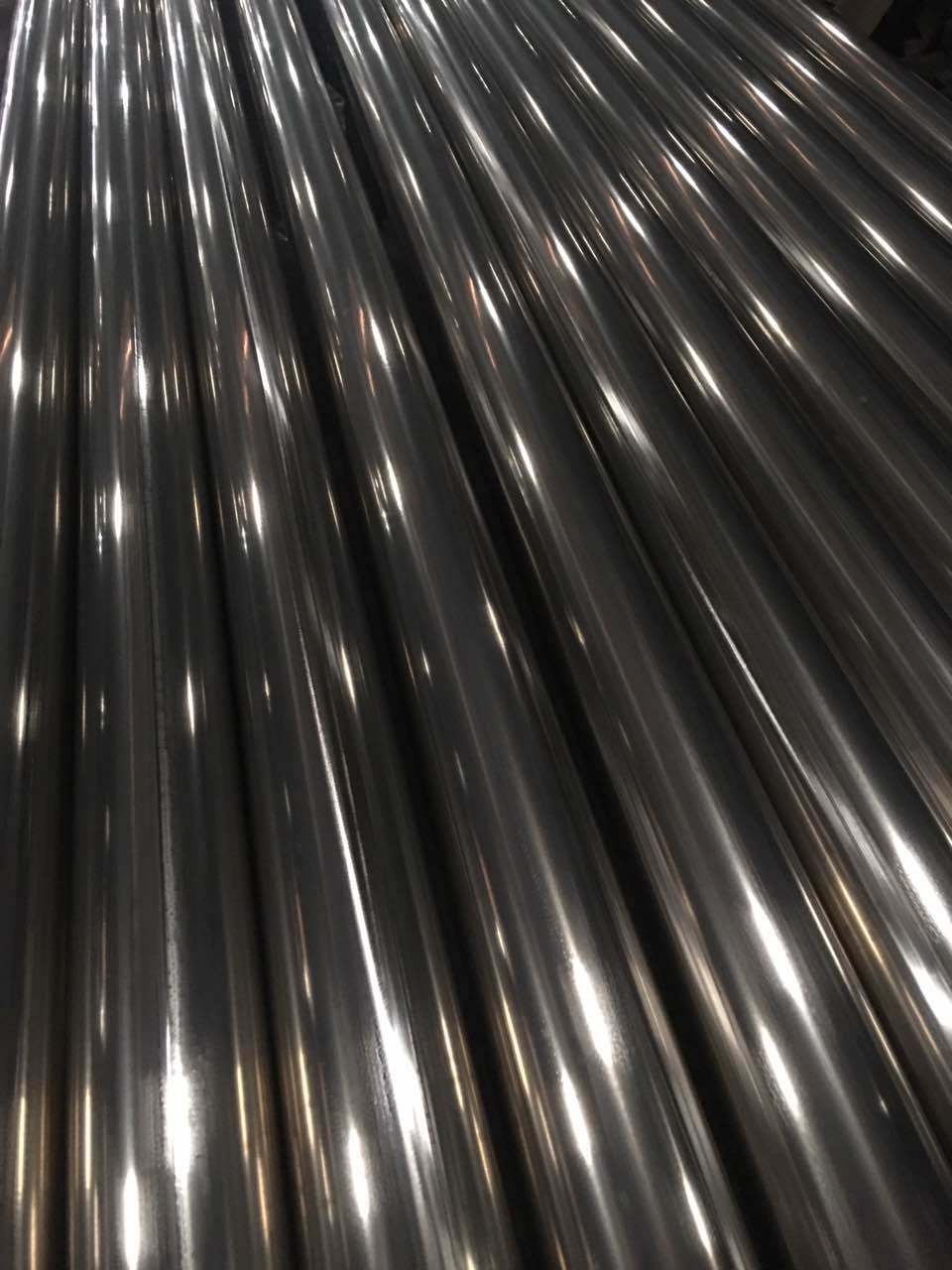

(1)O.D.: Φ8-Φ25mm

(2)Wall thickness: 0.3-1.0mm (square pipe and special-shaped pipeδ≤1.0mm)

(3)Length: 4~8M

1.4 Product (steel pipe) process flow:

Raw material (steel coil) → uncoiling → shearing and butt-welding → material accumulating → non-power leveling →mill-forming → high-frequency welding → removing burrs outside of weld seam → cooling → sizing → roughly straightening → fixed length cutting → run-out table

1.5 Milling speed: 20-90M/min (the speed is depended different pipe diameter standard and material thickness.)

1.6 Solid state high-frequency electrics power: 60 KW

1.7 Advised user's necessary accessories (only for reference):

(1)Mechanical equipment site: 35M ?/span> 4.0M (length ?/span> width)

(2)Electrical equipment site: 5M ?/span>3M (length ?/span>width)

(3)Machine unit foundation base (See supplier's base drawing)

(4)Two sets of 3-ton overhead crane

(5)Power supply:

a. Equipment motor: 22KW 4KW 1.5KW= 27.5KW

b. Solid state high-frequency electric: 60 KW

(6)Saw blades (Disk) for tracking saw, specification as per instruction book and quantity as per customer need.

(7) Magnetic bar (Impeder core) for welding pipe, purchase as per pipe making size. Normally,>(8)>Φ2 ' , 6M high-pressure pumps for high-frequency electric and pipe-welding machine cooling. This device will be matched by buyer.

(9)>(10) Machine unit electric circuit. Before assembling, circuit must reach the electric cabinet of high-frequency room. The electric connection joint of high-frequency room is to overall control table and button station. (Decide size and quantity when installation>(11) High-frequency room for machine unit. It is adopting ground or attic according to customer's layout.

(12)>(13) Lifting equipment and tooling for installing machine, maximum weight of>2. Introduction of main components:

2.1 Uncoiler:

Structure type: Double-side 360簉otary manual expanding tight, which insure steel coil feeding alternatively and make steel strip going into accumulator freely.

Applicable range:

Steel strip width: 25-80mm

Thickness: 0.3-1.0mm

Steel coil O.D.:Φ800-Φ1000mm

Steel coil I.D.:Φ350-Φ450mm

Steel coil weight: Max.800kgs

2.2 Shearing and butt-welding machine, which insure double steel tidily and then welding and leveling weld seam

2.3 Accumulator:

(1)Structure: Cage-type plate-welded part with automatic feeding and delivery system.

(2) Adjusting method: Manual spiral adjusting.

(3) Accumulating volume: 150-300M.

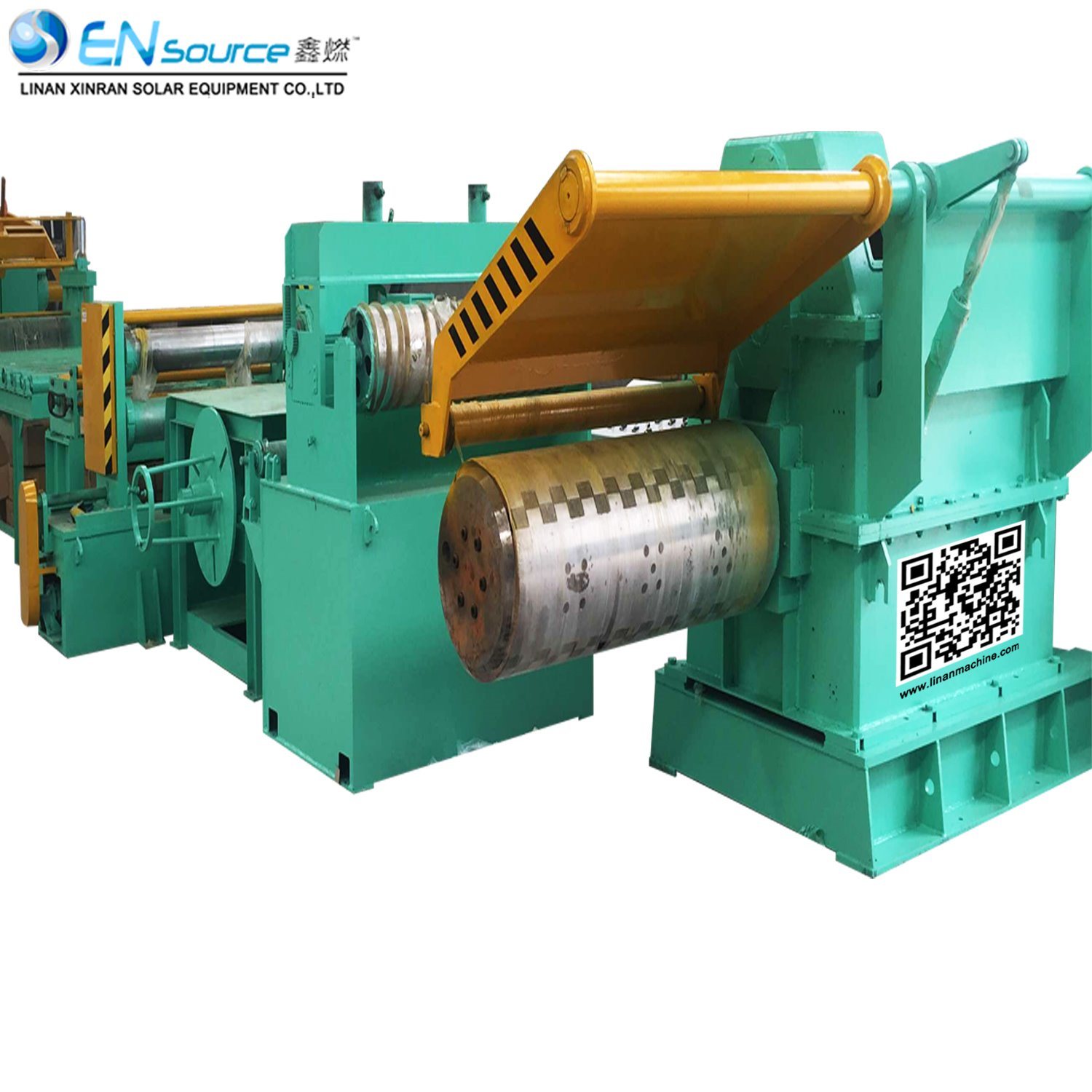

2.4 Forming, welding and sizing unit:

(1)Feed leveling device:

a. Type: 7 rollers are passively leveled for leveling strip steel to make steel strips go into forming device.

b. Guiding roll:>(2)Forming device:

Mainly roughly mill-forming steel strip and controlling weld seam.

Forming roller material: Cr12 (HRC58~62)

a. Horizontal roll stand:

Quantity: 8

Structure: 45# steel, double housing, changing roller in the side

Diameter of horizontal roll's shaft: Φ36mm, material: 42CrMo

b. Vertical roll stand:

Quantity: 8

Type: Passive rotation

Diameter of vertical rollers' shaft: Φ20mm, material: 45# steel

c. Drive gear box

Quantity: 4

Structure: Spiral bevel gear, cylindrical gear

Material: casing: QT50, gear: 20CrMnTi and 40Cr, input and output shaft: 40Cr

Drive transmission: 16 sets of CA141universal transmission shaft

d.>(3) Guiding extruding and welding scraping apparatus:

a. >b. Two sets of extruding roll stand is used to control welding seam to realize successful welding.

c. Two sets of scraper frame for scraping outside weld seam

d. Installation bed along with forming machine

(4)>(5) Sizing device:

Mainly function is to fine shaping pipe after welding and controlling size accuracy. Each 6 sets of horizontal roll stand, vertical roll stand and drive gearbox, 12 sets of universal shaft.(structure same as forming device)

(6) Roughly straightening machine frame:

a. Type: Turk's head type, 4 rolls two sides

b.> (7) Driving system: The main unit is connected with main reduce by major motor and transmits power to gearbox branches, then gearbox branches drive upper and down shafts>a. Main motor: Z4 series, DC22KW >b. Main reducer: ZLY160-4.5(outside four-shaft ends) >2.5 Computer-controlled tracking cutting saw:

- Cutting method: Computer-controlled tracking and automatic cutting

- Cutting thickness: δ0.3-1.0mm

(4) Cutting length: 4-8M

(5) Cutting tolerance: ≤?mm

(6) Cutting motor: 4KW, second-class AC motor

2.6 Finished pipe conveyor: (Run-out table)

Welded frame structure equipped with sizing signal system

2.7 Solid state high-frequency electric: 60KW

Applicable power supply 380V/220V 60HZ

NOTE: WHEN THE LINE IS SHIPPED, THE SELLER WILL SUPPLY SOME NECESSARY SPART PARTS FOLLOWING THE LINE SHIPPING.

Turbine ventilators

Inquire

Inquire

Other Products