Basic Info

Basic Info Product Description

Product Description

China Straight Seam High Frequency Welded Tube Mill

Basic Info

Product Description

- Model NO.: FX45

- Condition: New

- Theory: Pulse

- Type: Pipe Making Machine

- Origin: China

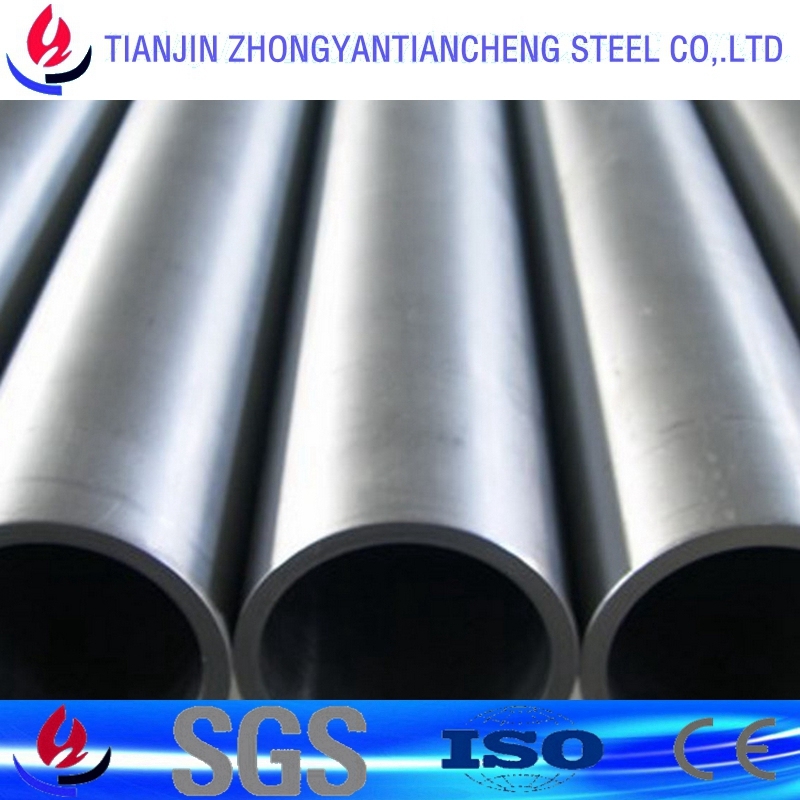

- Pipe Material: Carbon Steel

- Customized: Customized

- Application: Industry

- Transport Package: Wooden Box

- HS Code: 8515219100

Welding Pipe Production Line

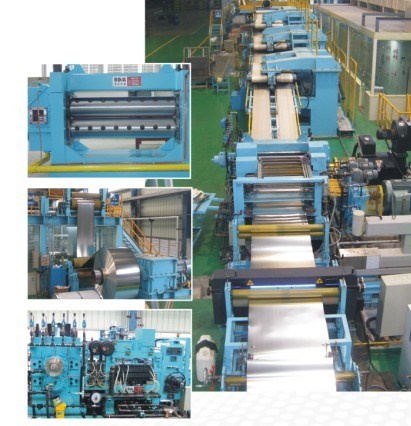

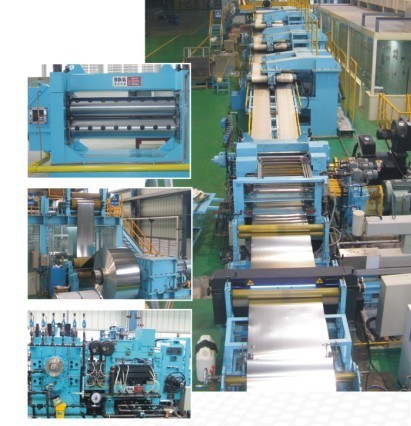

High frequency welding machine is a strip as raw material, after uncoiling, molding, high frequency welding, sizing, straightening, cutting off a series of pipe forming process to produce complete sets of equipment or a variety of circular steel tube steel pipe line.

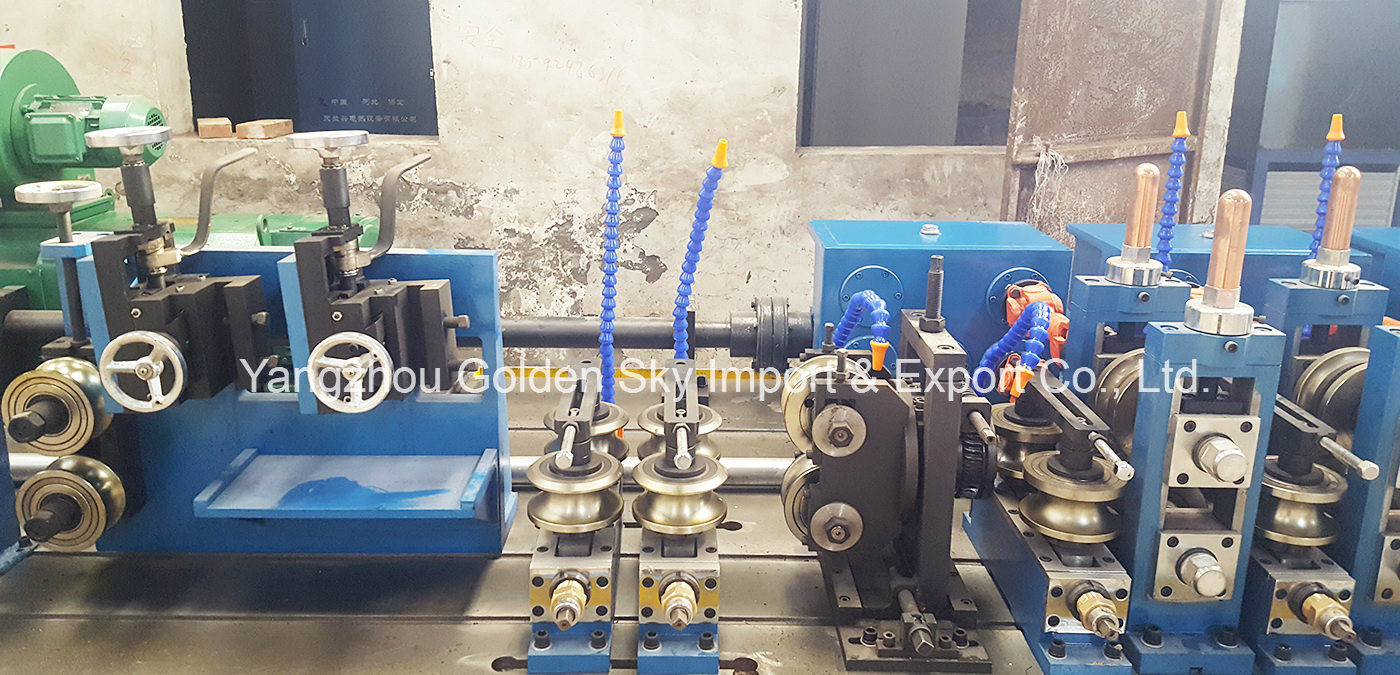

Roll forming is used to make the strip cold bending into round billet, and the welding seam is extruded to form round tube by high frequency induction heating. Various standard tubes and square tubes are produced after sizing.

INTRODUCTION OF MAIN EQUIPMENT

NO.EQUIPMENTINTRODUCTION AND MAIN TECHNICAL PARAMETERSMANUFACTURER(1)Raw material uncoilerIt's used to support the steel strip roll and feed raw material for the production line.1) Structure modeDouble working position2) Material tray outer diameterΦ1500mm3) Material tray inner diameterΦ350 - Φ550mm4) Central height1000mm5) Weight bearing3000Kg(2)Shearer and butt welderIt's used to weld together the tail of former material roll and the head of next roll to ensure the continuous production of pipes.1) ShearingResponsible for shearing irregular parts of two material coils and making preparation for welding.2) WeldingResponsible for connecting head and tail of two steel strip rolls.(3)Vertical material accumulatorIt's used to store and feed raw materials for the forming machine so that the machine can work continuously.1) Max storage capacity150-300m2) Power of driving motor5.5Kw3) Max material feeding speed150m/min(4)Forming and sizing machineIt's the main equipment of the production line. Rollers can make steel strip form into pipes of variety shapes. It consists of forming part , welding part and sizing part.1) Forming partMaterial feeding - Flattening - Feeding - 1 Horizontal roller - 1 Vertical roller - 2H - 2V - 3H - 3V - 4H - 4V - 5H - 5V - 6H - 6V - 7H - 7V2) Welding partSeam direction guiding -Extruding - Welding - Weld burr removing - Polishing - Water cooling3) Sizing part1V - 1H - 2V - 2H - 3V - 3H - 4V - 4H - 5V - 5H - 6V - 6H - Speed measuring - Straightening4) Driving method110Kw DC motors transmit power to gear boxes through reducer, then gear boxes transmit power to each horizontal roller through universal shafts.5) Horizontal rollersUsing gantry type integral frame. Diameter of shaft is Φ55mm and the material is 40Cr.6) Vertical rollersAdjusted through lead screw. Diameter of shaft is Φ35mm and material is 40Cr.(5)Computer flying sawWith the high precision STD control system and quick reaction of mechanical system, the cutting saw has reliable synchronization performance and high precision cutting length.1) Error in length?mm2) Power of cutting motor11Kw3) Power of driving motor11Kw4) Specification of saw pieceΦ50爪?50?.0mm(6)Automatic pipe unloading platformIt is an unloading platform of pipes cut by computerized saw. After the pipes falling down, workers can quickly check the quality and package them for preparation of transportation.(7)High frequency induction appliancesUsing the current skin effect and proximity effect of high frequency to make both edges of the material rapidly heated to soldering temperature and then weld them together. Using computer to monitor the process can provide the machine with reliable quality.

PRECISE FOUR

Inquire

Inquire

Other Products