Basic Info

Basic Info Product Description

Product Description

China Weld Seam-Inside Leveling Machine (BGP-40/50/60/80/100)

Basic Info

Product Description

- Model NO.: BGP-40/50/60/80/100

- Place of Origin: Foshan, China

- Warranty:>

- Certificate: ISO9001

- Brand: Bg

- Trademark: BG

- Origin: China

2. Introduction:

The stainless steel welded pipe is better than the stainless steel seamless pipe in material and mechanical property. But the elimination for the weld seam inside and outside, especial the weld seam inside have been puzzling the manufacturer of stainless steel pipe. Althought have the solution of drawknife grind device inside, it can not have much help, which have been blocking the development of the stainless steel welded pipe industry. At present, oil, chemical, nuclear power, boiler, medicine industries mainly use stainless steel seamless pipe.

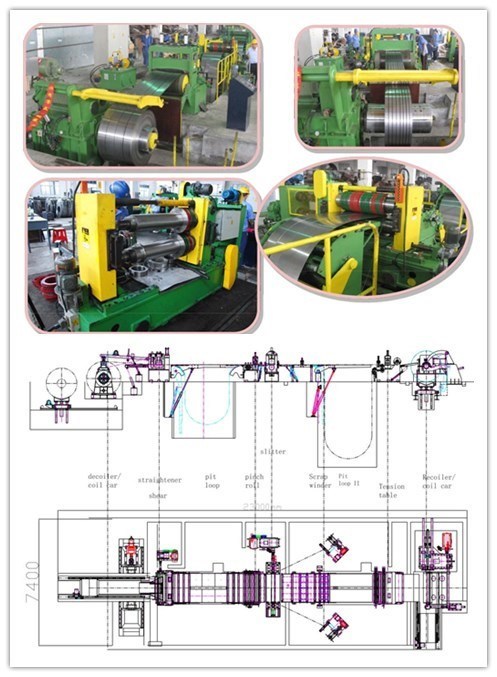

3. Component:

Inside and outside weld seam leveling equipment, hydraulic air control system, auto electric hydraulic air control system with PLC, hydraulic cycling equipment for mold and roll.

4. Feature:

Stainless steel welded pipe welding leveling device and a built-in mandrel and utilization of stainless steel welded pipe rolling device automatic reciprocating roller, through the control to achieve the strength and make stainless welded pipe and weld leveling, completely remove the internal and external welding and more with respect to requirement, the score is popular, the seamless steel tube welding.

5. Working procedure:

With more than the high and weld stainless welded pipe after level after rolling roll over, high removed, welded pipe section into a level in welding rods, elliptical stuck pipe welded pipe, followed by vertical roll rolling, welded pipe section into a mandrel, with full welded pipe separation in the frame of the cylinder back to when proper place, then the second rolling cycle. Model Diameter Thickness Production Speed Power BGP-40 O. D. 12-51mm 0.5-2.0mm 0-6m/min 7.5KW BGP-50 O. D. 32-76mm 0.5-3.0mm 0-6m/min 11KW BGP-60 O. D. 50-114mm 0.5-3.5mm 0-4m/min 11KW BGP-80 O. D. 89-168mm 0.5-4.0mm 0-3m/min 15KW BGP-100 O. D. 100-219mm 0.5-6.0mm 0-2m/min 15KW BGP-100 O. D. 150-273mm 0.5-8.0mm 0-1.5m/min 18.5KW

PRINTING UNIT

Inquire

Inquire

Other Products