Tube mill machine,pipe mill machine,stainless seel welded pipe

China Factory Price Welding Pipe Production Line with Good Quality China Manufacturer

China Factory Price Welding Pipe Production Line with Good Quality

Basic Info

Model NO.: WB-TM

Weight: 12t

Voltage: 380V 50Hz 3phase

Warranty: 12months

Market: Global

After-Sales Service Provided: Engineers Available

Trademark: WB

Transport Package: Export Standard Packing

Specification: EXPORT QUALITY WITH CE SGS CERTIFICATE

Origin: China

Product Description

Factory price welding pipe production line with good quality

Introduction

This equipment is specially used for producing Carbon High Frequency Welded Pipe Mill. It made by refined materials in high precision and equipped with fixed length cutting saw. The main machine includes forming, welding, sizing and straightening device. The composition of equipment is from decoiler to fixed length-cutting saw. Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

Process

Raw material (strip steel roll) - Material feeding - End cutting and butt welding (hand welding) - Strip storage cage - Material feeding and forming - High frequency welding - Removing outer burr - Cooling water jacket - Fix the diameter and straightening - Cut off with flying saw - Material unloading (Manually stow and bind up)

Inspection - Storehouse

Technical Data

Description

WB12

tube mill line

WB25

tube mill line

WB32

tube mill line

WB50

tube mill line

Diameter of welded tubes

Φ7-25mm

Φ8-32mm

Φ13-50mm

Φ20-60mm

Wall thickness of welded tubes

0.3-1.0mm

0.4-1.5mm

0.6-1.8mm

0.8-2.7mm

Speed of tube welding

90M/min

90M/min

90M/min

70M/min

Power of major motor

22KW

37KW

55KW

75KW

Power of high frequency welder

60KW

60KW

100KW

100KW

Machine components

Uncoiler

Cutting and Butt Welding (provided by user)

Storing Chamber/Spiral looper

Forming and sizing & high frequency Welder

Computerized Flying Saw

Output table

Pictures for reference

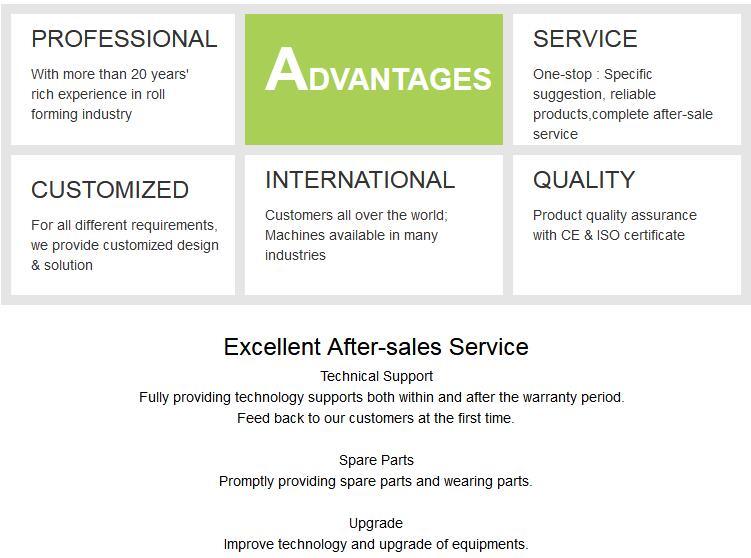

Our Advantages

Exhibition

Certifications