Basic Info

Basic Info Model NO.: HJ-3

Product Description

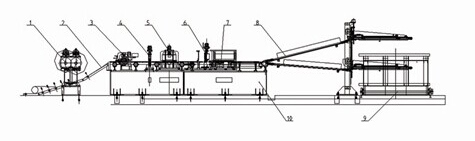

China Cut-to-Length Line for Transformer Lamination (HJ-300/400/600/900)

Basic Info

Model NO.: HJ-300/400/600/900Product Description

Application:This machine is the latest special equipment for transformer lamination manufacturing.

Components:

- Twin-head decoiler

- Buffer mechanism

- Feeding and measuring mechanism

- O Punch

- V Punch

- Shearing unit

- Divert mechanism

- Conveying mechanism

- Magnetic adsorption stacking mechanism

- Stacking trolley

Functional features:

1. The device can complete automatic production of various sheets for laminated, full tapered seam cores.

2.Shearing power : imported electrical servo control technology is adopted, so the device is featured by high speed, low noise and long life.

3. Feeding power: adopt high torque AC synchronous servo motor, so has characteristics such as rapid response, high positioning and accuracy, low noise, low braking thermal loss and long life.

4.Track positioning: the centralized positioning is achieved by dragging the linear tracks>Note: Dimensions and product structure can be determined according to the specific technical protocol.

Technical Parameters:Parameter ModelHJ-300HJ-400HJ-600HJ-900Sheet width (mm)30-34040-44060-64070-920Sheet length(mm)250-1500350-2500400-3500400-5000Sheet thickness(mm)0.23-0.35; 0.35-0.5Accuracy in length≤?span style= ' font-family:Calibri; ' >0.2mm/mRemained shearing burr≤0.02mmAccuracy of shearing angle?span style= ' font-family:Calibri; ' >0.025?/span>Feeding speed0-240 m/mincutting time per time≤200 sLife time of tooling 1.2 million timesMax step width40 mmCutting steps1,2,3,4,5,6,7Positioning ModeCentralized positioningStack madeBackward pushingHuman-machine interfaceTouch screen with 64 keysInstallation capacity15 kw20 kw30 kw35 kwRated capacity12 kw14 kw16 kw18 kwOverall dimension10m ?/span> 4m ?/span>1.8m15m ?/span>5m ?/span>2m18m ?/span> 6m ?/span>2.5m22m?/span> 6m ?/span> 2.5m

Processing:

Decoil the raw material, feed with a fixed length via the servo motor, shearing it with various shearing tools into sheets of various types according to the drawing and then piling them>

Rain downpipe

Inquire

Other Products