Basic Info

Basic Info

Product Description

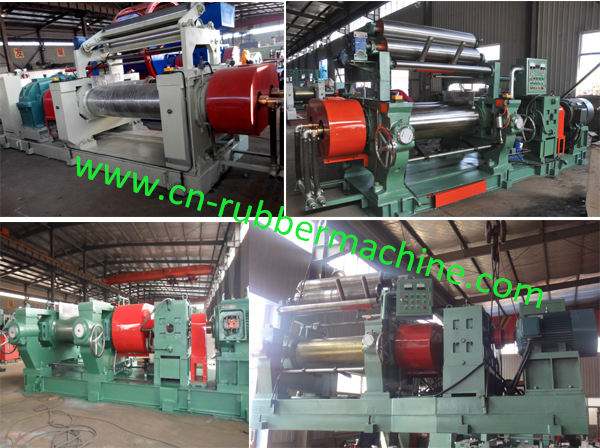

China 22" Rubber Mixing Mill with ABB Motor, Rubber Mixing Mill

- Model NO.: 22 '

- Control Type: Artificial

- Power Source: Mechanical

- Voltage: 380V

- Power: 110kw

- Customized: Customized

- Front Roll Diameter: 550mm

- Roll Working Length: 1530mm

- Trademark: SFC

- Specification: ISO9001: 2008, CE, SGS

- HS Code: 8477800000

- Warranty: 1 Year

- Automatic Grade: Manual

- Type: General Rubber Machinery

- Certification: ISO, CE, SGS

- Using Life: Longer Than15 Years

- Model: Xk-560

- Rear Roll Diameter: 510mm

- Capacity Per Batch: 35-50kg

- Transport Package: Standard Export Packing or as Your Requested

- Origin: China

STRUCTURAL FEATURES:

1. 22 ' Rubber Mixing Mill with ABB motor is ZSY series hardened reducer, six precision carburizing and tooth grinding cylindrical gears, low noise, long life and large endurance; roller bearing using fully automatic lubrication system specially designed sealed structure to eliminate oil spills.

2. Have a high degree of humane design: the nearest workspace design, operating system and user-friendly operation and reducing the labor intensity of workers.

3. This 22 ' Rubber Mixing Mill with ABB motor is overall welding pedestal, single shaft drive structure, compact structure, safe and reliable, simple to find the level of equipment when shipped to the client's company, simply connected into the return water pipeline, power line work can be carried out installation and debugging convenient.

3.1 Roller temperature adjustment device: using high quality rotary joint, high pressure hose, water pipe additional shut-off valve to facilitate equipment maintenance, with connection into the backwater pipe bluing and user-friendly plumbing connections.

3.2 Cutting device: the cutting device with two movable blades, users may need to adjust the cutting spacing to have different width rubber sheets.

3.3 Rack, gland: welded steel plate processing after annealing treatment.

3.4 Stock pan: made of welded steel plate.

3.5 Roller: roller using alloy chilled cast iron, the front and rear rollers can be made of hollow light roller, so as to achieve better temperature control. Work surface hardness is 68 - 72HSD.

3.6 Roller bearings: High-precision self-aligning roller bearings.

3.7 Nip adjustment device: manually controllable pitch worm screw driving and have electric and manual two modes.

3.8 Stock guide: steel made fixed type.

3.9 emergency brake: emergency stop button way, rack around with four emergency stop buttons.

3.10 Safety device: safety chip breaking pressure 110 /- 3t to protect the main parts from damage.

3.11 Base: steel plate welded structure, machined after annealing.

Product Certificate:

Qingdao Shun Cheong Machinery Co., Ltd is the professional manufacturer of various vulcanizing press and press machine. Our company has passed ISO9001: 2008 Quality Management System Certification and our products have qualified with Sweden SGS Certificate, and CE Certificate.

Salient Features:

1. Superior Mixing Performance.

2. Low Operating Cost with High Productivity.

3. Compact Construction, maximum Floor Utilization.

4. Latest Technology Update, Meets Current World Standards.

5. Maintenance Free.

6. Reliable and Experienced Service Back Up.

7. Easy to Install & Ready to Run.

8. No continuous Lubrication hence heavy saving>Test Before Delivery:

In order to save time and cost for customers, we produced rubber mixing machine at the factory wires between the motor and the control cabinet already connected, the customer's>ItemXK-160XK-250XK-360XK-400XK-450XK-550XK-560XK-660XK-710Roll diametermm160250360400450550560-510660710Roll working length 320620900100012001500153021302200Front roll linear speed r/min916.316.719.321.822.527.22831.9Speed ratio of rolls 01: 01.401: 01.101: 01.301: 01.301: 01.301: 01.201: 01.201: 01.201: 01.5Max roll space mm4.5810101216150.5-150.5-15Compound feeding capacitykg1-210-1520-2518-355050-6550-65165190Motor powerkW5.518.530455511090240280Dimensions(L?W?H) Lmm113327224200492054056646627072808185Wmm92011151780178017402736228234003910Hmm139413451760180017902105200025302270Gross weight T~2~3.2~6.5~8~11.4~22~22.5~49~51

Our Services

1. Our engineers can design target machines for customers and send them the drawing to confirm. We are always>FAQ

1. Delivery time of the rubber machines?

This is specially designed machine according to your specific requirement.

From engineer designing to production completion, it needs about 25 to 35 days.

2. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production.

Every machine will be fully assembled and carefully tested before shipment.

3. What's the machine quality guarantee?

Quality guarantee time is>Packaging

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

There are 15 experienced engineers and 108 skilled workers in our company, guaranteeing delivery />In addition, our machineries have exported to America, Mexico, India, Vietnam, South Africa, Singapore, Malaysia, Indonisia, Australia, Sri Lanka and many other countries.

If you interested in our products mentioned above. Kindly let us know by return email. Then I will supply you with further information. Meanwhile, welcome to visit our factory!

Qingdao Shun Cheong Machinery Co., Ltd.

Shandong, China

Manufacturer/Factory

- Sample Available

- OEM/ODM Service

- Russian Speaker

- Factory Tour

- Plate Vulcanizing Press

- Rubber Mixing Mill

- Lab Mixing Mill

- Rubber Kneader

- Waste Tire Recycling Line

- Rubber Calender

- Batch-off Cooler

- Rubber Bale Cutter

- Rubber Extruder

- Conveyor Belt Splicing Press

- Rubber Tile Vulcanizing Press

- Rubber Extrusion Vulcanizing Line

- Conveyor Belt Vulcanizing Press

- Tire Tread Vulcanizing Press

- Reclaimed Rubber Production Line

UNCOILER

Inquire

Other Products