Basic Info

Basic Info Model NO.: HFSL

Product Description

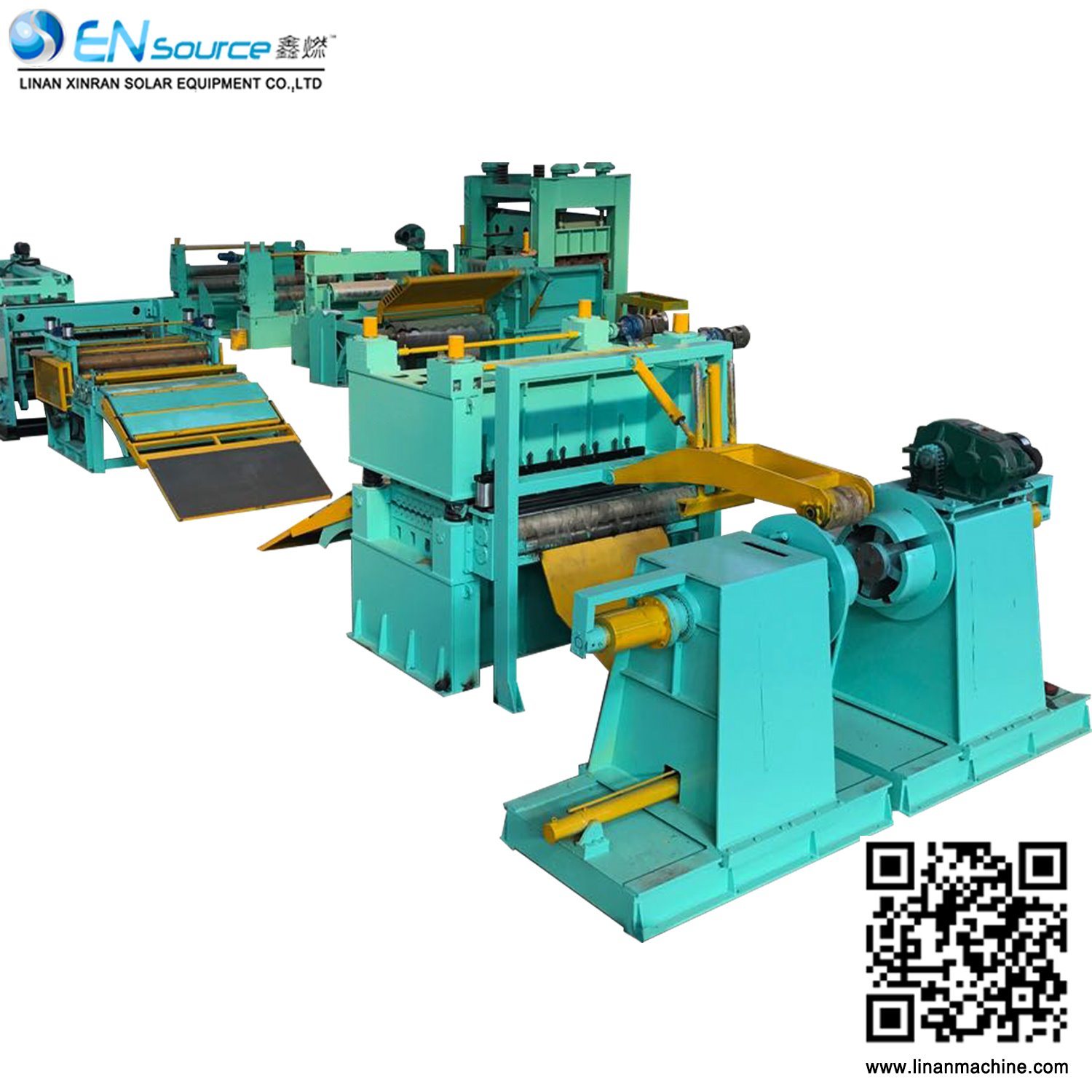

China Jinan Huafei Slitting Line with Low Price

Basic Info

Model NO.: HFSLProduct Description

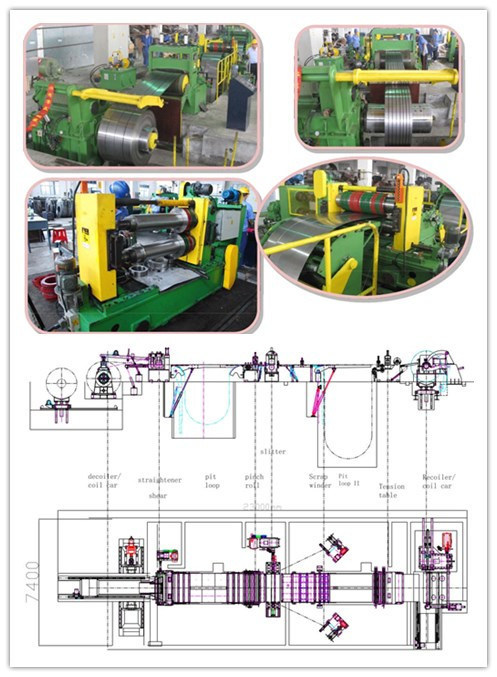

1.Entry Coil Car Functionputting coil>StructureCoil car is composed of lifting frame and moving trolley.Features1).V-shape frame coated with rubber plate, raised and lowered by a hydraulic cylinder. Guided by guide pillar.

2).The car is driven by motor and moves along rails.

3).Oil pipe and cable protected by towline.2.Functionuncoiling coil plate for further processing.3. Material-guiding Device Functionguiding material plate into leveling machineStructurecomposed of Straight head rollers and material-supporting tableFeatures1).Hydraulic swing type

2).material-supporting table lifted by hydraulic cylinder4. Material-guiding and Leveling MachineLeveling plate for slitting and dragging un-coiler to work composed of a pair of pinch rollers and three work rollers 1).Top pinch roller raised and lowered by motor

2).Pinch rollers and bottom work rollers rotates initiatively.

3).AC motors driven

5. Crop ShearFunctioncutting off irregular head, Features1).Hydraulic drives type.

2).Downwards shearing.

3).Gear and rack of knife holder drive synchronously.6. Loop Table1).Table coated with good PVC plate, raised and lowered by hydraulic cylinder

2).Arc-shape frame is composed of supporting rollers and coated with corrosion preventive and wearproof rubber.

3).Two pairs of Photo sensors installed to control strip level. 7. Side GuideFunctionCorrecting strip direction, preventing it from deflecting and feeding it into slitter.Structure

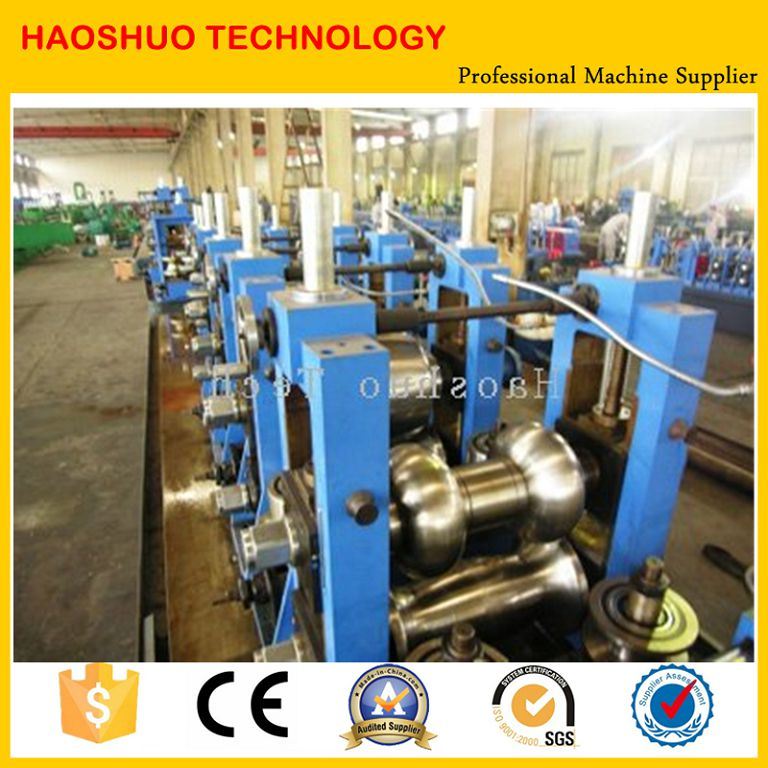

Composed of vertical guide rollers, movable sliding base, screw sliding rail and adjusting hand wheel.8.Slitter machineFunctionCutting plate into required width strips.Features1).Slitter arbors are rotating initiatively. Driven by AC motor, reducer, gearbox and universal joint shaft.

2).Motorized adjusting geared sleeve eccentric position by worm wheel to change slitter arbor clearance for adjusting blade overlap.

3).Many knives and different thickness spacers>9. Scrap Winder (two sets)FunctionRecycling waste edges cut by slitting machineFeatures1).Torque motor drive. Speed and winding torque is adjustable.

2).The drum expands and collapse for unloading scraps easily.11. Separator (2 sets)FunctionSeparating slitted strips to avoid material tangling when going through tension unit.Features1).Two sets of separator shafts can be moved from operating side. Easy to exchange.

2).An anti-jump pressing roll attached.12. Tension UnitFeatures1).Hydraulic pressing table type.

2).Pressing slide block raised and lowered by hydraulic cylinder. Pressure can be adjustable.

3).Presser foot with ridges

13. Deflector Roll&Feed Plate1).The polyurethane coated deflector roll installed at the end of tension pad, with the measuring encoder attached

13. Deflector Roll&Feed Plate1).The polyurethane coated deflector roll installed at the end of tension pad, with the measuring encoder attached2).Feed plate feeds strips to clamp jaw easily. 14. Recoiler machine1).Single cantilever type

2).Four segments. Hydraulic expansion,With clamp jaw.

3).Drum FWD and REV driven by DC motor, reducer and driven gear.

4).Installed with hydraulic separating pressing beam.

17. HydraulicsFeatures1).Hydraulic system pressure

17. HydraulicsFeatures1).Hydraulic system pressure2).Integration pumping station and valve block installed.

3).Hydraulic components are high quality brands from Taiwan and mainland China, Others are Chinese high quality brands18. Lubrication SystemGearbox and reducer lubricated by oil pool. Others lubricated by distribution grease pump or gun

19.Electrics1).380V, 3-phase, 5 wires, voltage fluctuation should be within ?0%, AC220V and DC24V for control power.

19.Electrics1).380V, 3-phase, 5 wires, voltage fluctuation should be within ?0%, AC220V and DC24V for control power.2).PLC control, working speed of slitting machine and recoiler machine can be controlled synchronously

3).3 kinds of working modes provided: adjusting, manual and automatic, thus automatic running of single-machine and line can be well met.

4).different control panels for a convenient operation, touching screen for main control panel

5).features of self-diagnosing and exhibition of speed and length. 1PLCMitsubishi 2transducerOmron 3DC speed controllerImported brands 4pulse encoderImported brands 5Touching screenImported brands 6Photos-witchImported brands 7buttonChina top brands 8othersChina top brands

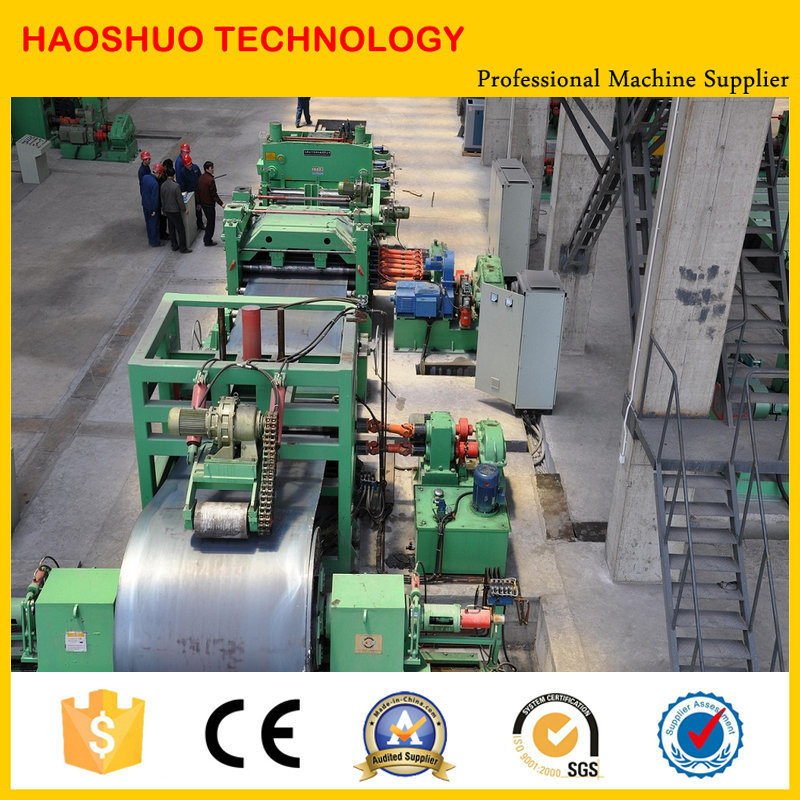

HOT-DIP GALVANIZING(ALUMINIUM) LINE

Inquire

Inquire

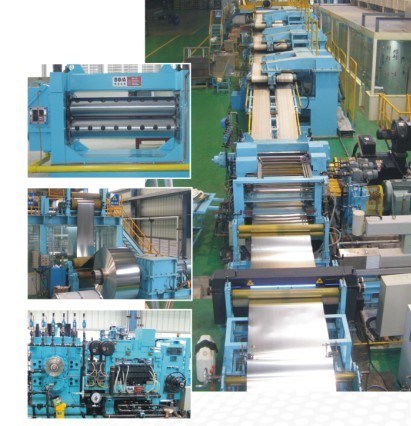

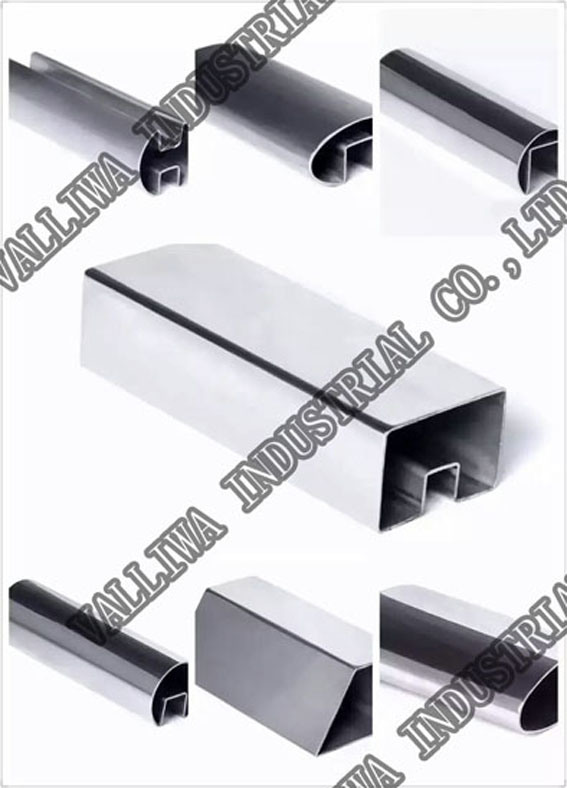

Other Products