Basic Info

Basic Info Product Description

Product Description

China API Standard Carbon Steel Welded Pipe Tube Mill

Basic Info

Product Description

- Pipe Material: Carbon Steel

- Customized: Customized

- Application: Industry, Decoration

- Trademark: Wanxin

- Specification: customerized

- Condition: New

- Theory: Inverter

- Type: Pipe Production Line

- Transport Package: in Container

- Origin: Hebei Rprovince of China

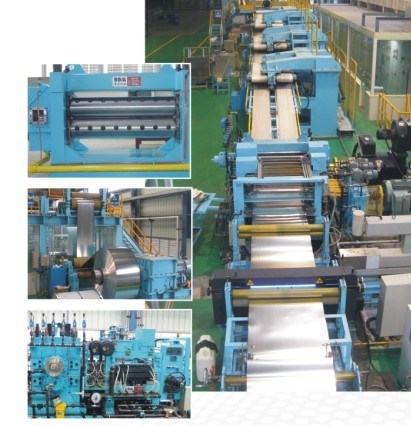

ERW steel pipe production line: At first, the coil is loaded at the uncoiler, then but-welding the ends of coil, delivering to accumulator. After accumulator, the strip is pulled from accumulator contentiously by fixed speed, is formed to opened-pipe at forming machine, then welded by High frequency welder, deburred, cooled, shaped and sized as round pipe and rectangular&square pipe at the sizing area. Then the sized pipe is straightened after Turkey-head device and then cutt to fixed length by flying saw. At last, the fixed pipe is delivered from run-out table and inspected at the table.

This line could produce the round pipe, the rectangular and square pipe by material of cold/hot-rolled coil etc. It could be used at the metallurgy, construction, transportation, machinery, automobile industry. Adopting ' W ' forming type, it could make much more reasonable force, and much more perfect forming shape at each stand etc.

Technical process:

Double workstation uncoiler→Hydraulic shear & end welder→Accumulator→Forming and sizing machine→Flying saw→Run-out table→Packing machine

Main equipments:

1. Double workstation uncoiler

Function: to unwind the coil.

Structure: it has two mandrels mounted on a 180?swiveling bearing. One mandrel remains in line with pipe mill during operation while coil is loaded on other mandrel at backside by buyer supplied jib crane. Coil will be expanded or shrinked by hydraulic sliding block. Mandrels will stop swiveling by Pneumatic butterfly valve.

Advantage: fast feeding speed (one mandrel is for use, the other mandrel is for stock), easy operation.

2. Shear & end welder

Function: to shear and butt-weld the trailing end of a proceeding coil and the leading end of the next coil.

Structure: consist of manual shear, pre-after pinching roll, pre-after middle roll and welding equipment.

3. Accumulator

Function: to store material for forming and sizing machine, and assure continuous production of forming and sizing machine.

4. Forming and sizing machine

Main technical specification:ItemParameterForming Way: ' W ' Roller forming wayWorking height:+850mmMain Power:DC (or AC) motor:90kw, 1000-2000r/min, 1setReducer:Harden gear reducer ZLY280-6.3, 1setPress material method:Manual worm and worm gear

Arrangement mode:

Passive five roller leveling, feed material vertical roller, 8 forming leveling, 8 vertical, guiding, squeezing, shaving scar, cooling, sizing, 6 leveling, 5 vertical, rough straightening, (1 turkey-head stand )

Main parts structure:ItemParameterTurkey head:1set, 8 rollers, each side with 4 rollers

Φ30mm, 40Cr, quenching, tempering & hardeningLevel rollers and material:Φ45mm, material 40Cr, inner diameter of bearing: 40mm, quenching, tempering & hardeningHeat treatment: level rollerSurface quenching, HRC50-55Bearing slider:45#forgingVertical rollers and material:Φ30mm, material 40Cr, quenching, tempering & hardeningStruture of level roller & vertical roller:Gantry, distance between 2 level roller frame: 110mm,

squeezing of level frames: worm gear adjusting.

Vertical rollers: Manual silk pole adjusting.Material of level roller & vertical roller:Welding (aging annealing)Gear box:Gear: spiral bevel gear, 20CrMnTi, Module M=8,carburizing and quenching.

Box: ZG 35# cast iron. Chain gear to connect between the boxes.

Universal transmission shaft to connect the shaft of lever roller & output shaft of the gear box. Shaft distance: 400mmShaft of squeezing roller:Φ50mm, with two rollers to squeeze which is adjusted by manual silk pole.Shaft of guide roller:40mmBlades for scrape scar:Two pcs with one working and the other one is for emergencyWater tank:2m

5. Computer control flying saw

Function: to cut the pipe in setup length during the high speed producing.

Structure: consist of mechanical bed system, gear transmission system, saw cutting system, driving system, and speed testing system.

6. Delivery track, run-out table, pipe stocking table & packing machine

Function: to deliver finished pipes to pipe stocking table by deliery track and pack pipes with hexagonal shape by packing machine.

Remark: we are manufacturer for steel pipe making machine, strip/coil slitting line, sheet shearing machine, hot dip galvanizing line, etc. If you are interested with our products, pls kindly send me your requirement by email . Also you can chat with me by WhatsApp or Wechat, which are same with my mobile number: zero zero eight six one eight five three eight one two nine two eight six.

About Wanxin Ocean:

Beijing Wanxin Ocean International Co., Ltd ( Hereinafter referred to as Wanxin Ocean) is an integrated import & export company, specialized in supplying large mechanical equipment and service, providing mass goods, steel plate, steel pipe, etc.

Wanxin Ocean is located in Beijing, China, being a member of Wanxin Group, which also include another two factories in Hebei province, covering 22,400m?period; Depending on powerful R & D and manufacture ability, Wanxin Ocean can supply you the superior machines and service.

Wanxin Ocean is located in Beijing, China, being a member of Wanxin Group, which also include another two factories in Hebei province, covering 22,400m?period; Depending on powerful R & D and manufacture ability, Wanxin Ocean can supply you the superior machines and service.

About Wanxin Group:

- Beijing WanXin Ocean International Trade Co., Ltd. --- Machine & Steel Products Exporter (Founded in year 2014) www.wanxinocean.com

- BaZhou WanXin Industrial and Trading Co., Ltd. --- Factory I (Founded in year 1997)

- BaZhou WanXin Roller Co., Ltd. --- Factory II (Founded in year 1992) www.cnwanxin.cn

Wanxin Group (Bazhou Wanxin Industrial and trading Co., Ltd, Bazhou Wanxin Roller Co., Ltd, Hebei Brilliant Steel Pipe Co., Ltd, and Beijing Wanxin Ocean International Trade Co., Ltd) was founded in 1992, and Located in Bazhou city, Hebei Province, covering 224,000 square meter. Wanxin is a high and new- technology enterprise, which is specialized in design, development and manufacture of ERW welding pipe production line, high precision slitting & cut to length equipment, HF welding H-beam steel production equipment, spiral welding pipe mill, cold roll forming production line, hot dip galvanizing line and rollers. Wanxin is the pioneer to develop the key processing technology and the international advanced whole set of welding tube mill. Wanxin always adhere to the policy ' Quality is the priority ' . With excellent quality and competitive price, Wanxin products are very popular at home and abroad. Wanxin products are sold in more than 20 provinces in China and have been exported to more than 20 countries like Bangladesh, Philippians, Thailand, Malaysia, Ethiopia, Iran, Uzbekistan, Ukraine, Indonesia and Venezuela.

Stainless Steel Welded Pipe Mill

Inquire

Inquire

Other Products