Basic Info

Basic Info HS Code: 846880

Product Description

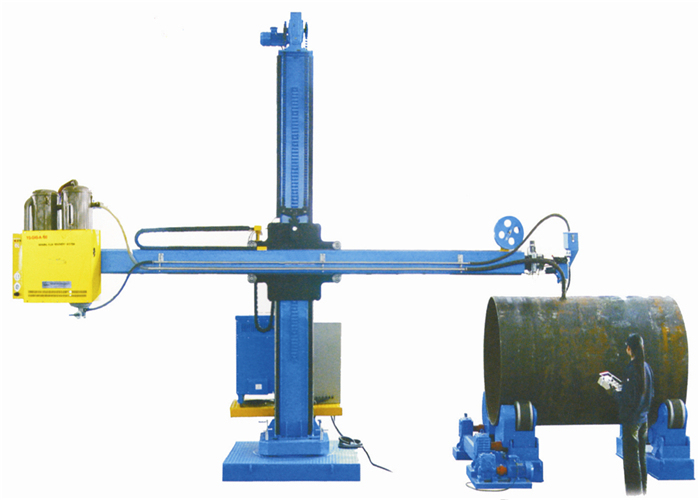

China Automatic Welding Center with Welding Manipulator/Rotator/Positioner

Basic Info

HS Code: 84688000Product Description

Welding centre is specially designed the for various geometric shape work piece, and is widely used in boat manufacture, chemical industry, petrol chemical industry, building, boiler & pressure container, power industry and etc..Welding center is commonly used for cylinder longitudinal seam and circle seam processing.

1, HJ6060 type welding manipulator;

2, HGZ-20A self adjusting roller frame;

3, MZ-1000 automatic sub-merge arc welder.

Main equipment parameters:

HJ6060 type welding manipulator.

Features:

1, HJ welding manipulator has good guide seat strain, wide guide wheel connecting facet, and stable transmission hinge.

2, The machine is made up of standing column, cross arm, guide device, elevator and stairs and rail.

3, The standing column is rectangle beam, rectangle double slide structure. The standing column plates are assembled and welded, and through internal stress elimination, and machining. The clamping way of standing column and guide seat is 3 facet clamping each slide, more stable than triangle slide.

4, The cross arm is assembled with plate, rectangle double slide structure, machined after welding and tempering.

5, The lateral movement is adjusted by frequency converting motor, which drives the specialized worm gear and worm reducer to drive worm gear and worm. The welding speed can be adjusted in a range with different need.

6, The cross arm and standing column all used large section rectangle beam structure to ensure well strength. The slide processing is large gantry gate milling machining, so the deformation is small, surface accuracy high.

7, Welding arm for-end is fixed with cross adjustment device, to make welding gun pointing to exact welding seam, and it is easy to adjust.

8, Standing column head is fixed with cross arm elevator device, realized by AC motor, which drives worm gear and worm reducer. There's both worm gear and worm as well as AC motor for double insurance. There is jujube jujube wheel mechanism height= ' 300px ' srcid= ' 4229755 ' width= ' 300px ' src= ' /upLoad/et30849302303223.jpg ' />

Max. Load weight: 20ton

Adaptable work piece diameter range: Φ 500-Φ 3500mm

Rubber wheel diameter and width: Φ 350?120mm

Metal wheel diameter and width: Φ 340?30mm

Roller linear speed: 6-60m/h

Motor power: 1.5kw

Speed adjustment method: Frequency converting step less speed adjustment.

HGZ-20 self-adjusting roller frame is consisted with active roller seat and passive roller seat which matched with each other. The distance from active roller seat and passive roller seat could be adjusted, according to the length of work piece.

The active roller seat, passive roller seat and installing socket frame are all welded parts, all the welding seam are welded according to same welding strength, and annealing treatment after welding, to eliminate welding internal stress and avoid welding and hot cutting deformation.

The distance between wheel are fixed, and for different work piece supporting requirement, the clamp frame will automatic open and meet the need. It is easy to operate, practical, convenient, and reliable.

Relavant products:

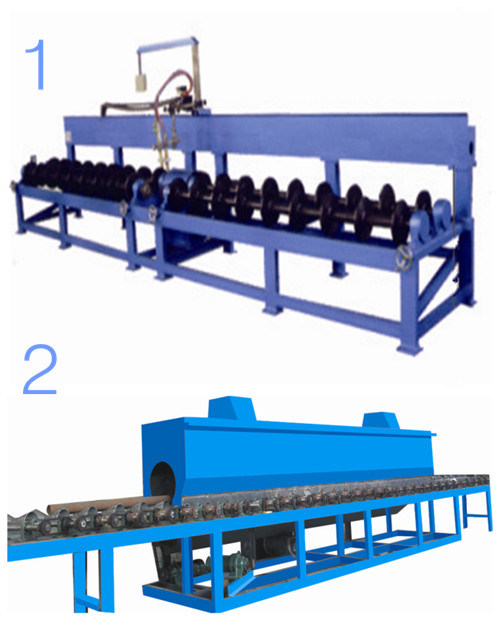

1, CNC pipe cutting machine.

2, Pipe shot blasting,anti-corrosion machine.

itemspecunitHJ6060 welding manipulator1cross arm vertical strokemm60002cross arm extension strokemm6000 two section extension structure3cross arm slide widthmm354standing column slide widthmm355guiding wheel seat supporting method

rectangle guide, support from three faces.5cross arm extension speedmm/min120-12006drive method

gear and gear rack drive7speed adjustment method

frequency stepless speed adjustment8cross arm extension motor powerkWlarge:0.55,small:0.379cross arm lifting speedmm/min50010drive method

Sprocket chain drive11standing column lifting motor powerkW1.512standing column rotary speedrpmby manual13drive method

rotary support14vehicle slide distanceMM200015travelling wheel diameterMMφ25016vehicle travel speedMM/MIN250017cross arm end load capacityA\ kg20018control wire lengthm1519equipment structure

rotary support20cross minor adjustment strokeup and downmm100left and rightmm100

PRINTING UNIT

Inquire

Inquire

Other Products