Basic Info

Basic Info Product Description

Product Description

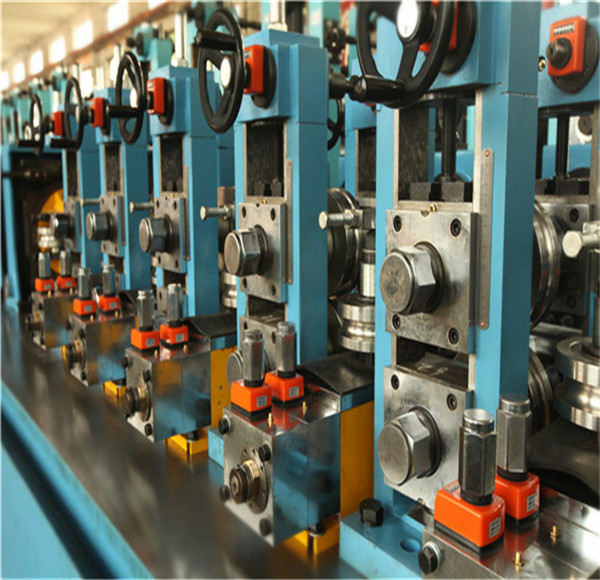

China Brand New & Used Welding Pipe Making Machine/Tube Mill/Pipe Mill

Basic Info

Product Description

- Model NO.: HG76

- Forging Forming Method: Roll Forming

- Feature: Precision

- Warranty: 24 Months

- Advantage: Easy to Maintence&High Presicion

- Strip Thickness: 1.5-4.0mm

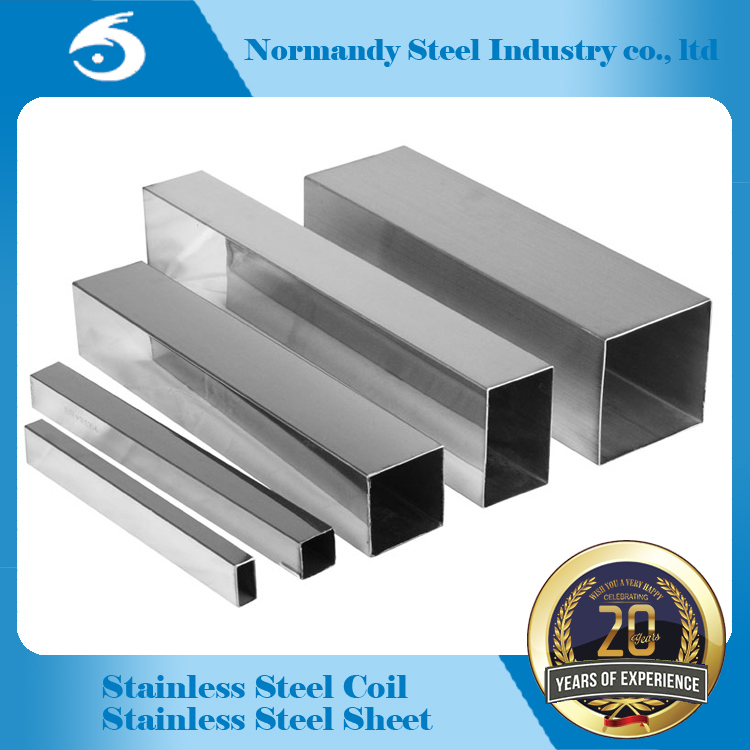

- Square Tube: 20*20mm~60*60mm

- Trademark: Forever tube mill

- Specification: 76mm

- HS Code: 8515219000

- Type: Roll Forming

- Power Source: Hydraulic&Electric

- Certification: ISO9001, CE

- Customized: Customized

- Condition: New

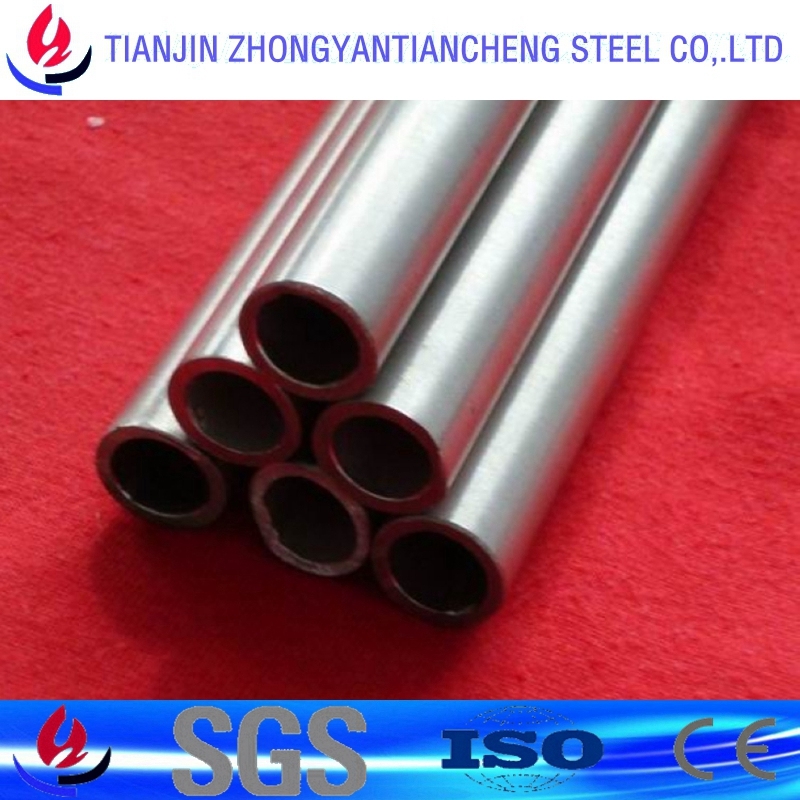

- O.D.: 25mm~89mm

- Line Speed: 15-60m/Min

- Transport Package: Pallet&Wooden Case

- Origin: China

High Quality Welded Tube Mill Line is a combination of equipment installed in a line for the production of High Frequency Induction Welded (HFIW) carbon steel tubes.The process involved is cold forming of carbon steel strip in circular shape, longitudinal welding, sizing, converting into specified shape and cutting to pre determined length.

The complete line is divided in three sections:Entry SectionForming, Welding, Cooling and Sizing SectionCutting and Delivery SectionRaw material (Steel Strip) in form of a coil is uncoiled and fed into forming section passing through the equipment of entry section.Entry section enables the tube mill to run continuously by using strip joining and accumulation equipment.Tube is formed in round shape passing through a set of driven and idler rollers of forming section before welding.In welding section tube is longitudinally welded by using high frequency induction welding method.Outside bead is removed and formed in shape of scrap.The weld seam is ironed and tube passes through the cooling section.In sizing section, tube is formed to specified size and converted into specified shape.After sizing, tube is cut to specified length by using flying cutting equipment and delivered in collecting troughs passing through run out conveyor.

ModelHG25HG38HG50HG60HG76HG140HG165HG219Diameter of welded tubes(mm)8-3210-38.113-50.816-6325-8940-14076-165114-219Wall thickness of welded tubes(mm)0.4-1.20.6-2.00.8-2.51.0-3.01.5-4.02.0-5.02.0-6.03.0-8.0Speed of tube welding(m/min)30-10030-8020-7520-6515-6015-5015-5015-40High frequency power

(KW)100150200200300400600800

Want to know more about us, please visit our website : www.frv.cn

Turbine ventilators

Inquire

Inquire

Other Products