Basic Info

Basic Info Model NO.: 28,

Product Description

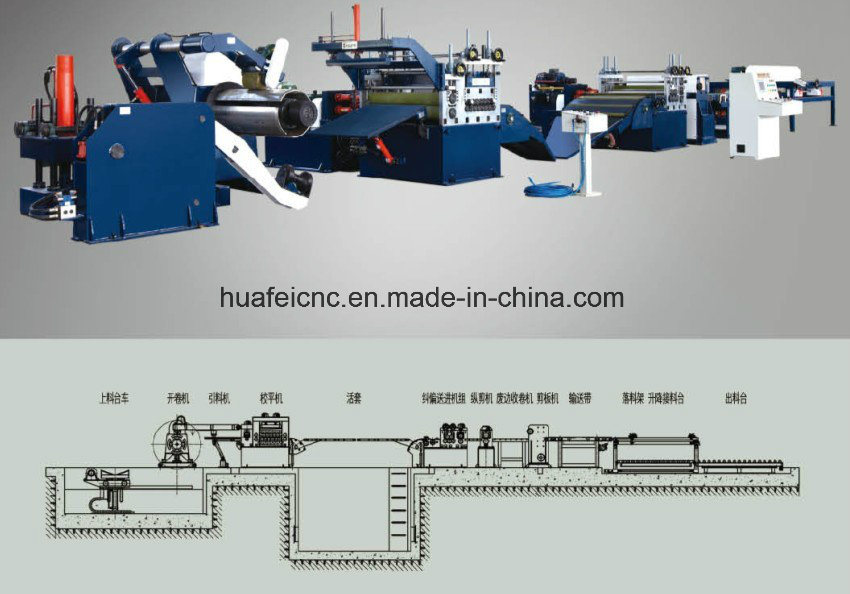

China High Frequency Welded Pipe Forming Machine

Basic Info

Model NO.: 28, 32, 50, 60, 76, 90, etc Cutter: Computerized Controlled Saw Cutter Cooling: Water Tank Shipment: in Hq Containers Warranty: One Year Trademark: Haoshuo Transport Package: Seaworthy Packing Specification: CE, ISO Origin: Jiangsu, China HS Code: 85152110Product Description

High Frequency Wedling Pipe Making Machine for Steel Pipe Production1.1 Summary:

This equipment is specially used for producingΦ 13-Φ 50.8mm(1/2'' 2''), δ 0.6-2.0mm high-frequency straight seam welded pipe and corresponding square pipe and special-shaped pipe(δ ≤ 1.5mm). The composition of equipment is from uncoiler to fixed length cutting saw. Rolling speed can be adjusted correspondingly within suitable range of pipe diameter and wall thickness.

1.2 Applicable material:

(1)Hot or cold-rolled steel strip (As per GB700-88 or GB1591-88)

(2)Material: Low-carbon steel, low alloy steelδ S≤ 345Mpa, δ B≤ 610Mpa

(3)The thickness of steel strip: 0.6-2.0mm (As per GB708-88)

(4)The width of steel strip: 40-160mm

(5)I. D. Of steel coil: Φ 450-Φ 550mm

(6)O. D. Of steel coil: Φ 800-Φ 1200mm

(7)Maximum weight coil: 1000kgs

1.3 Dimension range of processing steel pipe:

(1)O. D.: Φ 13-Φ 50.8mm(1/2'' 2'')

(2)Wall thickness: 0.6-2.0mm (square pipe and special-shaped pipeδ ≤ 1.5mm)

(3)Length: 4-8M

1.3 Milling speed: 20-90M/min

Work Flow:

Uncoiling -- shearing and butt welding -- material accumulating -- flattening forming system -- high frequency induction welding machine -- inside and outside burr removing frame -- water cooling system -- sizing system -- leveling system -- speed testing -- Turkish frame -- saw cutting -- running out table

Main components:

1 Uncoiler

2 Accumulator

3 Shearing and butt welding machine

4 Forming machine

5 Roller System of Forming

6 Seam Guide

7 High Frequency Induction Welding Machine

8 Roller System for Moving

9 Burr Removing Frame(Inside and outside)

10 Water cooling system

11 Sizing machine

12 Roller System of Leveling

13 Speed Testing Wheel

14 Turkish Frame

15 Auto flying saw controlled by Computer

16 Run-out table

17 Electric control Equipment

18High frequency welding machine

Pipe mill specsMachine

Model Pipe Diameter Pipe Size Thickness Speed Main

Power Welding

PowerWG-16Φ0.3~ Φ1.0inch

(Φ8mm~Φ25mm)7?mm

20?0mm0.3 ~ 1.2mm100m/Min22Kw60KwWG-25Φ0.3~ Φ1.2inch

(Φ8mm~Φ32mm)7?mm

25?5mm0.3 ~ 1.5mm90m/Min37Kw100KwWG-28Φ0.5~ Φ2.0inch

(Φ13mm~Φ50mm)10?0mm 40?0mm0.5 ~ 1.8mm90m/Min75Kw100KwWG-32Φ0.5~ Φ2.5inch

(Φ13mm~Φ63.5mm)10?0mm 50?0mm0.5 ~ 1.8mm90m/Min110Kw150KwWG-50Φ0.8~ Φ3.0inch

(Φ20mm~Φ76mm)16?6mm 60?0mm0.7 ~ 3.0mm80m/Min132Kw200KwWG-60Φ1.2~ Φ4.0inch

(Φ32mm~Φ102mm)25?5mm

80?0mm1.0~ 3.5mm70m/Min160Kw200KwWG-76Φ1.0~ Φ5.0inch

(Φ25mm~Φ127mm)20?0mm

100?00mm1.0~ 3.5mm70m/Min185Kw200KwWG114Φ1.6~ Φ5.0inch

(Φ40mm~Φ130mm)35?5mm

100?00mm1.5~ 5.0mm60m/Min160Kwx2400KwWG155Φ2.0~ Φ6.0inch

(Φ50mm~Φ155mm)40?0mm

120?20mm1.5~ 5.0mm60m/Min160Kwx2400KwWG165Φ2.0~ Φ7.6inch

(Φ50mm~Φ195mm)40?0mm

150?50mm2.0~ 6.0mm45m/Min200Kwx2500KwWG219Φ3.5~ Φ8.60nch

(Φ89mm~Φ219mm)70?0mm

170?70mm4.0~ 8.0mm40m/Min200Kwx2600KwWG273Φ4.0~ Φ10.7nch

(Φ100mm~Φ273mm)80?0mm

215?15mm4.0~ 12mm25m/Min320Kwx2800Kw

Integrated ceiling

Inquire

Inquire

Other Products