Basic Info

Basic Info Product Description

Product Description

Chinese High Frequency Welded Pipe Mill

Basic Info

Product Description

- Model NO.: JF76

- Customized: Non-Customized

- Application: Industry

- Seam or Seamless: Seam Pipe

- Voltage: for Different Needs

- Pipe Material: Carbon Steel, Iron, Stainless Steel

- Certification: ISO-9001-2000,Ce,SGS

- Product Name: Tube Making Machine

- Trademark: JiFu

- Specification: as per actual design

- HS Code: 8515219100

- Condition: New

- Theory: Inverter

- Type: High Frequency Weld Pipe Mill Line

- Warranty: 1 Year

- After-Sale Service: Engineers Available to Service Machine Overseas

- Power: for Different Needs

- Line Speed: 0-100 M/Min

- Thickness: 0.4-19mm

- Transport Package: by Sea

- Origin: Shijiazhuang

PRODUCT DESCRIPTION:

High-frequency ERW straight seam pipe making machine, for the whole prodcution line, at first, the coil is loaded at the uncoiler, then but-welding the ends of coil, delivering to accumulator. After accumulator, the strip is pulled from accumulator contiousely by fixed speed, is formed to opened-pipe at forming machine, then welded by High frequency welder, de-burred, cooled, shaped and sized as round pipe and rectangluar&square pipe at the sizing area. Then the sized pipe is straightened after Turkey-head device and then cutted to fixed length by flying saw. At last, the fixed pipe is delivered from run-out table and inspected at the table.

This line could produce the round pipe, the rectangular and square pipe by material of cold/hot-rolled coil etc. It could be used at the metallurgy, construction, transportation, machinery, automobile industry. Adopting ' W ' forming type, it could make much more reasonbale force, and much more perfect forming shape at each stand etc.

MAIN FUNCTIONS:

JF16 Pipe-making machine line mainly applied in manufacturing electronic heating pipes and refrigerators pipes and suitable sizing thin-wall pipes.

JF20, JF32, JF45 Pipe-making machine line mainly applied in manufacturing frame-tubes and fitness equipment tubes.

JF50, JF60, JF76, JF89, JF114Pipe-making machine line mainly applied in manufacturing frame-tubes and fitness equipment tubes.

JF125, JF165, JF219,JF273 Pipe-making machine line mainly applied in manufacturing API pipe, pressure transmission pipeline, pressure tubing(penstock) and structural tube.

BUSINESS RANGE:

The main products we predominately specializing producing and dealing with are cold-formed mechanical equipments, including:

- ERW pipe mill

- High precision slitting & cross-cutting machine

- Hot galvanizing pipe mill

- Cold forming steel mill

- Pipe rollers.

OUR MARKET:

Based on the rich experience in the industry and the growing trade business, the company is expanding the scope of business and building a solid partnership in fields of metallurgy, fabrication and construction, traffic engineering, mechanism and vehicle industry. Our business relationships mainly distribute in Southeast Asia, the Middle East, Africa, Eastern Europe, South America.

SPECIFICATIONS:

ADVANTAGES:

1.High pipe production pass rate;less waste of coils

2.Offer investment consultation on steel pipe production plant

3.Overseas service center available,one stop service for customized machine.Overseas installation and operating training.

4.One year warranty of the whole machine,Life-long technical support

5.Easy to operate,automatic control,low voice

GENERAL PROCESS:

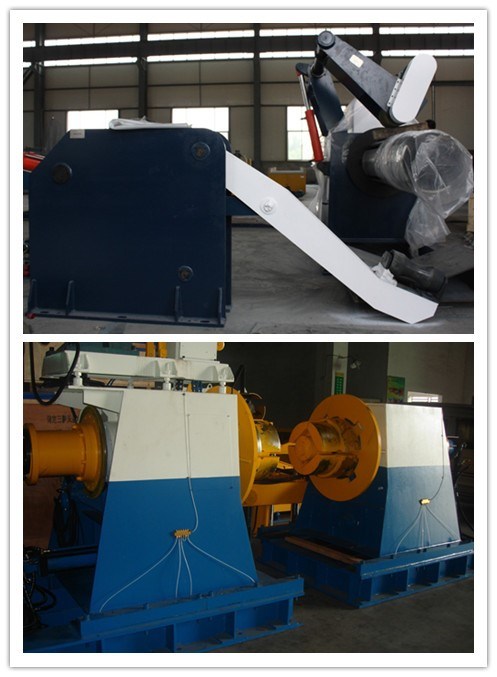

Double head uncoiler → Shear & butt welder → Accumulator → Forming section(flattening unit+mani driving unit+forming unit+guide unit) → High frequency welding unit+ squeeze roller → De-burr frame → Cooling unit → Sizing unit and straightener → Flying saw under computer control → Run out table

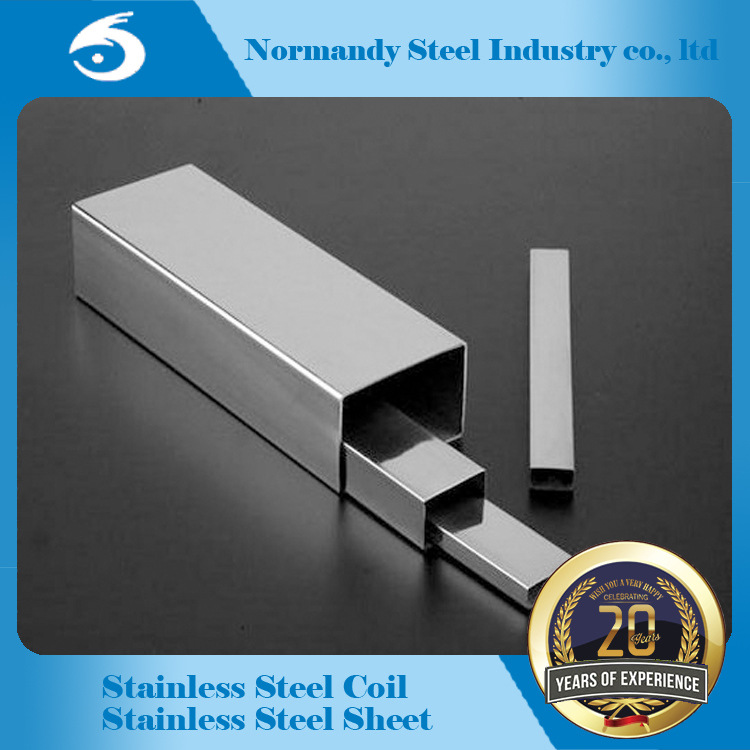

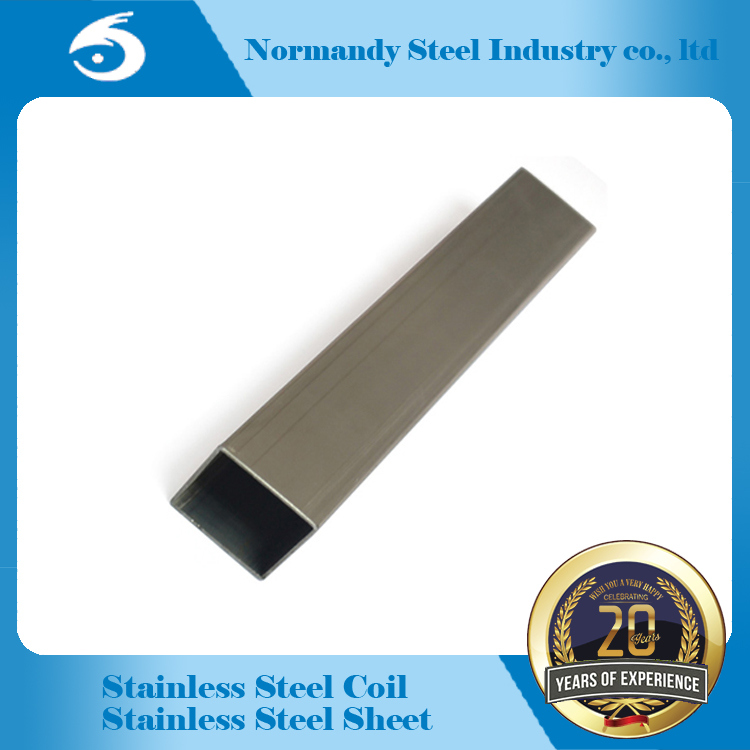

PRODUCT DISPLAY:

MAIN COMPONENTS:

1 Uncoiler

2 Accumulator

3 Shearing and butt welding machine

4 Forming machine

5 Roller System of Forming

6 Seam Guide

7 High Frequency Induction Welding Machine

8 Roller System for Moving

9 Burr Removing Frame(Inside and outside)

10 Water cooling system

11 Sizing machine

12 Roller System of Leveling

13 Speed Testing Wheel

14 Turkish Frame

15 Auto flying saw controlled by Computer

16 Run-out table

17 Electric control Equipment

18 High frequency welding machine

PRE-SALE SERVICES:

1). Offer honest and objective investment consultancy suggestion based on our many years engineering experience in the steel pipe industry.

2). Provide planning and implementation suggestion of plants for factory long-term and consistent development.

3). Share our analysis and forecast with clients the global trends of steel industry, especially the market in China.

4). Clients are welcome to visit the production line of steel pipe at our factory and our cooperated domestic customer factories.

AFTER-SALE SERVICES:

1). Our engineer will help you with machinery installation, debugging and operation.

2). Technical documentation and list of the main components are provided.

3). One Year Warranty(consumable parts or misused parts not included).

4). On-site service, machinery maintenance service and other related technical support are provided.

5). Your bridge to other related machinery supplier in China.

ERW Pipe Mill

Inquire

Inquire

Other Products