Basic Info

Basic Info

Product Description

China Forming and Sizing Mill for Steel Tube Making Machine

- Product Name: Auxiliary Equipment for Steel Pipe Welding Machine

- Uncoiler Strip Width: 250-1050mm

- Shear Welder Strip Width: 420-830mm

- Loop Diameter: 2.5-16m

- Loop Strip Thickness: 0.5-16mm

- Trademark: Lixing

- Specification: as per actual design

- HS Code: 8455900000

- Steel Pipe Diameter: 10-219mm

- Uncoiler Strip Thickness: 3-10mm

- Shear Welder Strip Thickness: 3-9mm

- Loop Strip Width: 60-1000mm

- Customized: Non-Customized

- Transport Package: by Sea

- Origin: Jiangsu, China

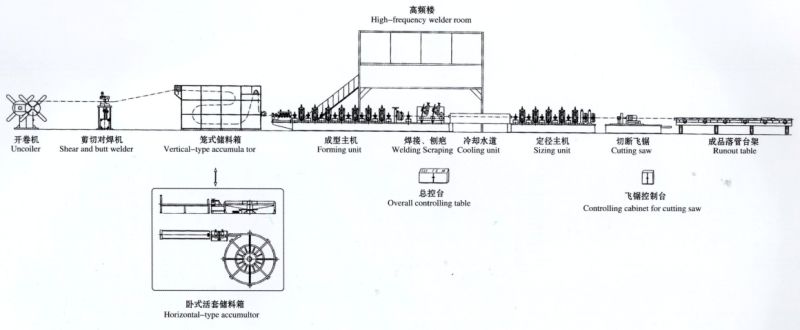

--Forming and sizing mill for Steel Tube Making Machine

1. Uncoiler/Uncoiling machine

1. Uncoiler/Uncoiling machine

Product description

Uncoiling machine is the main supplementary equipment in the welded pipe production line, it is used to support the steel strip and supply raw material for production, thus to assure the continuously production of the whole production line, brake style is controlled by whole linkage control, ensuring that the steel strip won't fall off during the production.

This machine consists of pedestal, double cones which can be contracted and expanded, rotary brace, pneumatic brake and electric control system.>Technical parametersProduct NameModelSteel strip width(mm)Steel strip thickness(mm)Single-head manual uncoiler/<=250<=3Double-head manual uncoilerYJ32<=100<=4YJ60<=200<=4YJ400<=420<=3Single-lead simple uncoilerYJ550<=550<=3YJ750<=750<=3Hydraulic uncoilerDouble-head<=1050<=10Single-head<=1050<=10

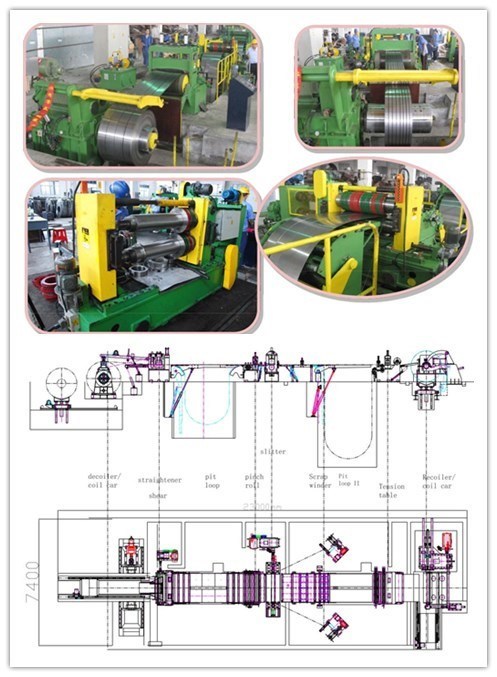

2. Shearing and butt welder

Product description

It is the essential equipment in ERW pipe and cold rolling production line; mainly used to cut off irregular ends in the beginning and the end of the steel strip, weld the ends, thus to ensure the continuous of the production.

Technical parametersProduct NameModelSteel strip width(mm)Steel strip thickness(mm)Shearing and butt welderYJ480<=420<=3YJ550<=520<=3Simple<=500<=3Shearing machineYJ600 Double column<=580<=6YJ600 Double column<=780<=8YJ600 Double column<=830<=9

3. Horizontal-type/Vertical-type Accumulator

Product description

The accumulator is the main supplementary equipment in the high frequency welded pipe and cold rolling production line. It stores certain amount of steel strips and leaves more time for the shearing and butt welder to shear and weld the ends of the strips. Thus ensures the continuous production process.

Technical parametersNo.Diameter(m)Steel strip width(mm)Steel strip thickness(mm)12.560-1800.5-2.023.560-2300.8-2.534.060-3500.8-3.044.280-4000.8-3.554.5100-4000.8-4.064.8100-4501.0-4.575.0120-5001.0-5.085.5150-6001.0-5.596.0180-7001.2-6.0108.0200-8001.5-8.01110300-8002.0-10.01212500-9005.0-12.01316500-10006.0-16.0

4. Forming and sizing mill

Product description

Forming and sizing mill is the main equipment in the welded pipe production line. This line can continuously process certain specification length of steel strips into pipe barrel and weld it into pipe. It can not>Technical parametersNo.Diameter(m)Steel strip width(mm)Steel strip thickness(mm)18-160.3-1.080-100210-260.5-1.580-100314-380.6-1.880-100420-63.50.8-3.070-80532-701.0-3.070-80640-801.0-3.560-70750-901.5-4.050-60860-1202.0-5.040-60960-1301.5-5.520-601080-1652.0-6.020-501189-2193.0-8.020-45

5. Flying/Cutting saw

Product description

Flying saw is the important equipment in the welded pipe production line; it is used for automatically and precisely adjusting and fixing dimensions to cut all different forms of pipe materials during its high speed running to produce the required steel pipe of certain length. The fixed-ruler is good at synchronous performance and reliable mechanical transmission, so this machine is integrated the merits of high-speed, well performance and high precision.

!! Any inquiry, please contact us.

Wuxi Lixing Metallurgy Machinery Co., Ltd.

Jiangsu, China

Manufacturer/Factory

- Factory Tour

-

Auxiliary equipment

- Steel Strip Uncoiler

- Spiral Loop/Accumulator

- Flying saw

- Forming and Sizing Mill

- Others Auxiliary equipment

- High Frequency Pipe welding machine

- Slitting cutting tools

- 0.15-20mm Slitting line machine

- 0.3-25mm Cut to length line machine

- Rolling mill machine

CATALYTIC INCINERATION SYSTEM

Inquire

Other Products